- hot selling products

- buying lead

- selling lead

- Library

- Answer

custom made nozzle tip tungsten carbide nozzle YG8Z made in China φ20.5*φ10*6.3*20.5

Product Image

Details Image

Design Image

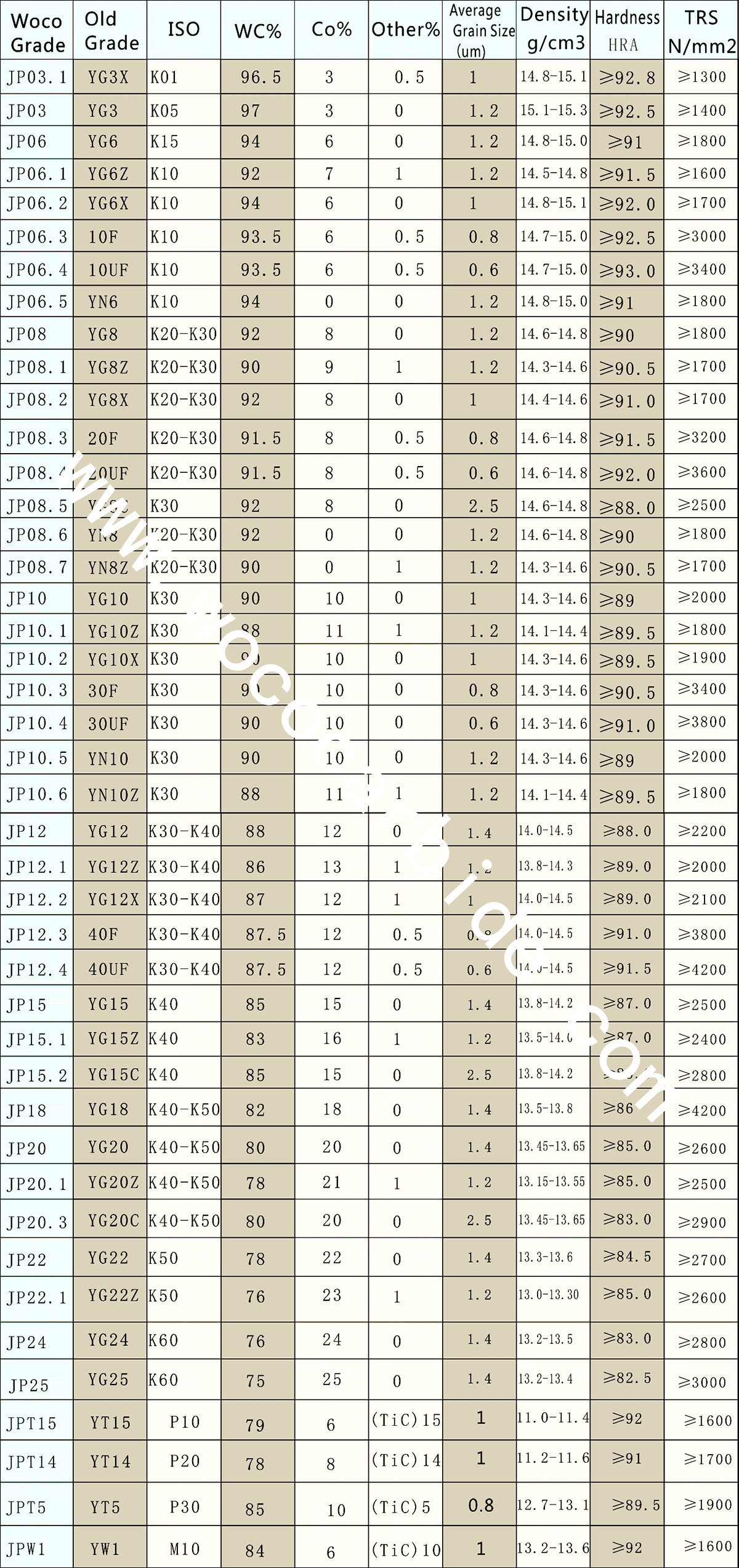

Composition

Performance Index

Application : chemical industry Food machinery Metallurgy architecture Derusting Cleaning Atomization

Packing Instructions

Description

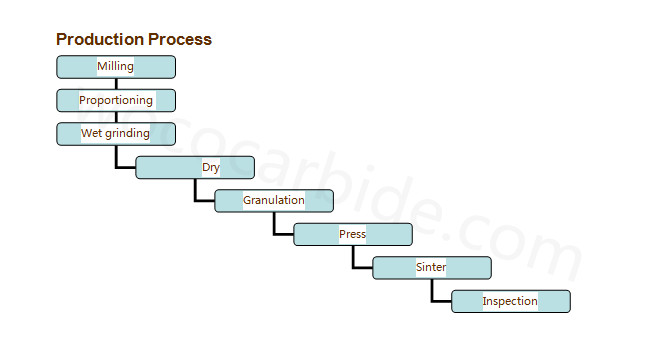

A nozzle is a device designed to control the direction of a particular gas flow (especially increasing speed) as it enters (or exits) a closed cavity or pipe. In terms of nozzles, carbide nozzles are the most rugged and cost-effective. The shape of the carbide nozzle hole determines its airflow pattern. The nozzle generally has a straight hole or a restricted hole, a small hole. 1. Straight hole: The straight hole nozzle works for airflow field or internal airflow to form a sealed airflow mode. This facilitates the realization of small jobs such as cleaning parts, weld forming, cleaning handrails, steps, lattices, or stone carvings and other materials. 2. The pore nozzle forms a sufficient airflow pattern that increases the grinding speed by up to 100% for a given pressure. The Venturi nozzle is the best choice for increasing productivity on larger surfaces. The long-nozzle nozzle can increase productivity by 40% compared to a straight-hole nozzle with approximately 40% less abrasive consumption. Due to the high thermal performance of the nozzle in general, the printing speed can be pushed even further without sacrificing the quality. The special shape inside the nozzle allowed by the manufacturing technique improves the flow where the diameter gets reduced, thus allowing a faster flow rate.

Hot recommended