- hot selling products

- buying lead

- selling lead

- Library

- Answer

High precision tungsten carbide nozzle YG8Z made in China

Product Image

Details Image

Design Image

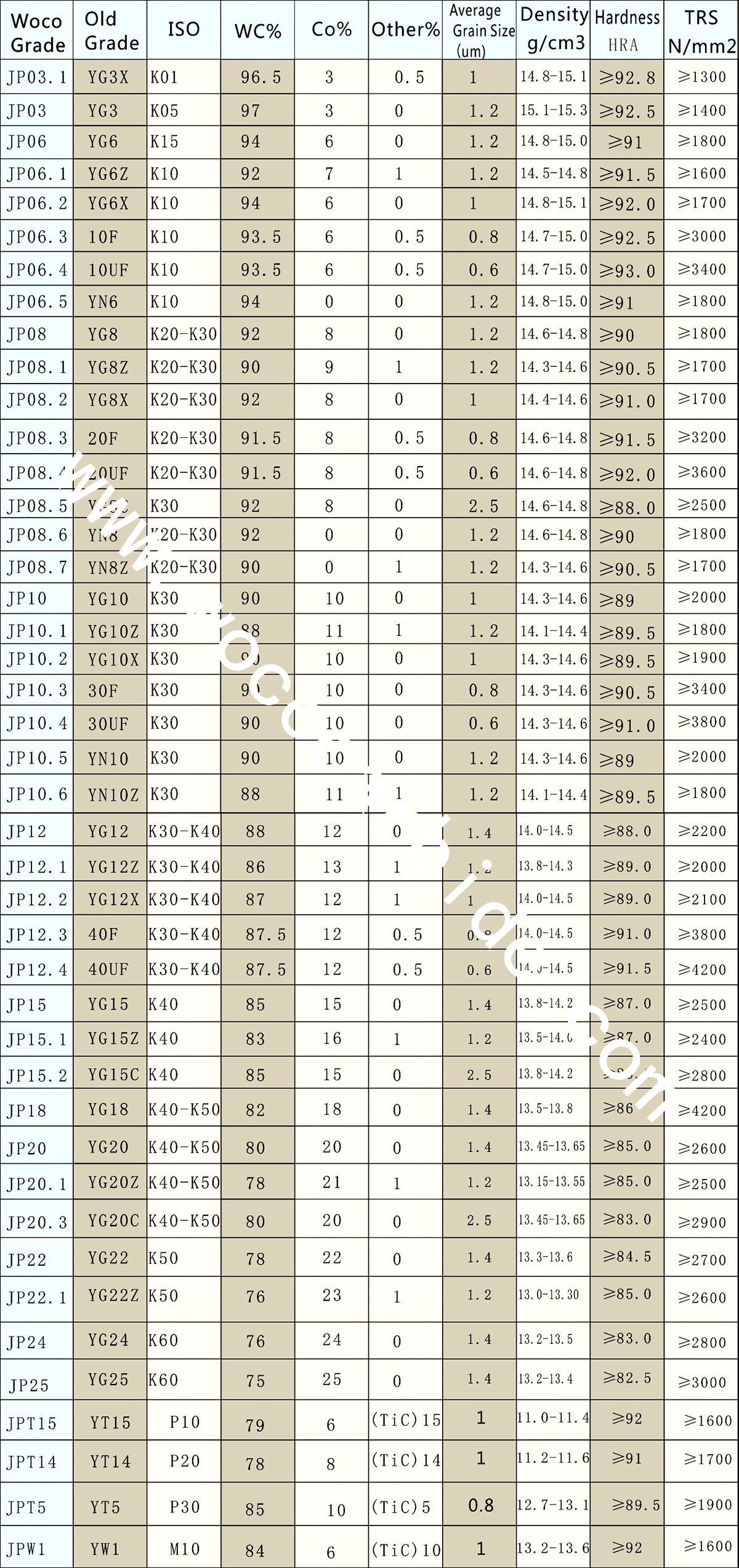

Composition

Performance Index

Packing Instructions

Description

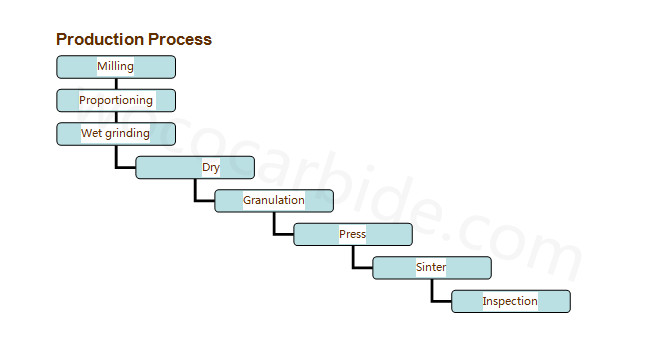

A nozzle is a device designed to control the direction of a particular gas flow (especially increasing speed) as it enters (or exits) a closed cavity or pipe. In terms of nozzles, carbide nozzles are the most rugged and cost-effective. The shape of the carbide nozzle hole determines its airflow pattern. The nozzle generally has a straight hole or a restricted hole, a small hole. 1. Straight hole (Carbide Nozzle 1): The straight hole nozzle works for airflow field or internal airflow to form a sealed airflow mode. This facilitates the realization of small jobs such as cleaning parts, weld forming, cleaning handrails, steps, lattices, or stone carvings and other materials. 2. Traditional long hill design (hard alloy nozzle 2) 3. The pore nozzle forms a sufficient airflow pattern that increases the grinding speed by up to 100% for a given pressure. The Venturi nozzle is the best choice for increasing productivity on larger surfaces. The long-nozzle nozzle can increase productivity by 40% compared to a straight-hole nozzle with approximately 40% less abrasive consumption. 4. Double Venturi (Carbide Nozzle 4): Double Venturi and Wide Throat Nozzle are enhanced versions of the long venturi nozzle. The style of the double hills can be thought of as having two nozzles between a set of splits and holes to allow the incoming atmosphere to enter the nozzles of the downstream section. The outlet end is also wider than conventional nozzles. These two modifications are designed to increase the size of the airflow pattern and minimize the rate of abrasive loss. 5. Wide throat nozzle (hard alloy nozzle 5): The wide throat nozzle has a large outlet and a large diverging outlet. When matched to hoses of the same size, they can increase productivity by 15% compared to a smaller throat nozzle. When the wide throat nozzle also has larger diverging outlets, they can use a lower abrasive usage mode at higher pressures to increase yields by up to 60%.

Hot recommended