- hot selling products

- buying lead

- selling lead

- Library

- Answer

YG8 factory wholesales wire drawing dies nibs 22*4.2*18

Product Image

Details Image

Design Image

Composition

Performance Index

Packing Instructions

Description

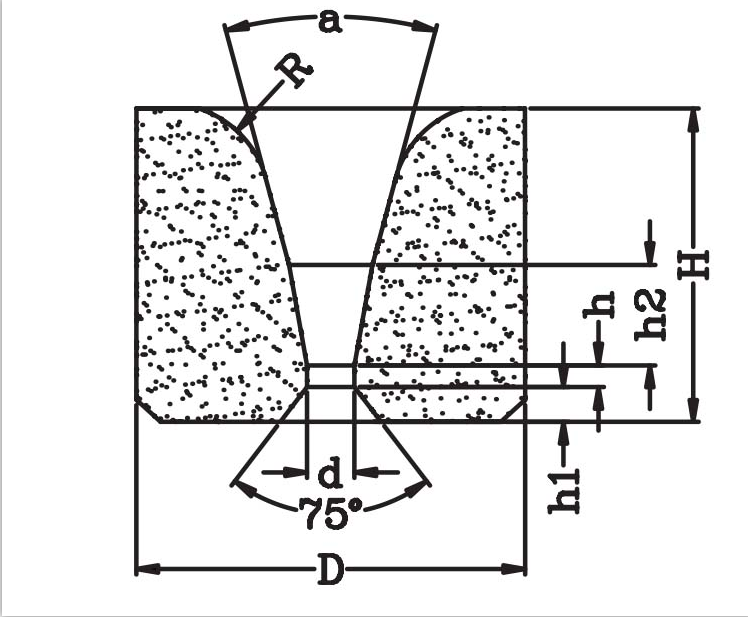

Straight wire drawing dies: it divided into 4 parts, The entrance area, work area, sizing area, exit area/un-lubrication area/lengthened work area, entrance area and work area are extended,, so that the wire enters the work area In the middle section, the wedge angle of the upper half of the working area and the upper half of the working area is used to establish a "wedge effect", and a denser and firm lubricating film is formed on the surface of the wire to improve the lubricating effect. However, there is no transition arc between the work area and the sizing area. More carbide drawing die information in wococarbide. During the drawing process, the wire and the wire forming surface are worn, and the test proves that the straight type is three to four times longer than the circular type.the sizing area. During the drawing process, the wire and the wire forming surface are worn, and the test proves that the straight type is three to four times longer than the circular type.

Hot recommended