- hot selling products

- buying lead

- selling lead

- Library

- Answer

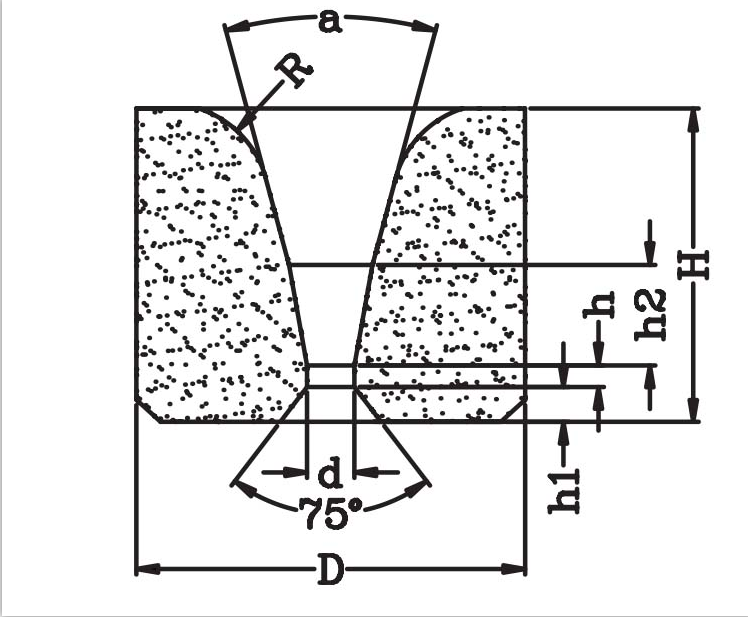

factory wholesales carbide wire drawing dies 22 * 5.7 * 19

Product Image

Details Image

Design Image

Composition

Performance Index

Packing Instructions

Description

What is the effect of stretching speed on tungsten-molybdenum wire drawing dies? Under certain other conditions, the average deformation speed increases with the increase of the stretching speed, the deformation heat effect increases, and the deformation temperature of the metal increases remarkably. More wire drawing dies in wococarbide. This phenomenon is particularly noticeable when using large deformation levels and high speed stretching. If the temperature is too high, the lubricant will easily fail and the lubrication conditions will deteriorate. At low speed stretching, the effect of reducing the deformation resistance of the metal is not obvious due to the small deformation heat effect, so the friction is large and the mold wear is severe.

Hot recommended