- hot selling products

- buying lead

- selling lead

- Library

- Answer

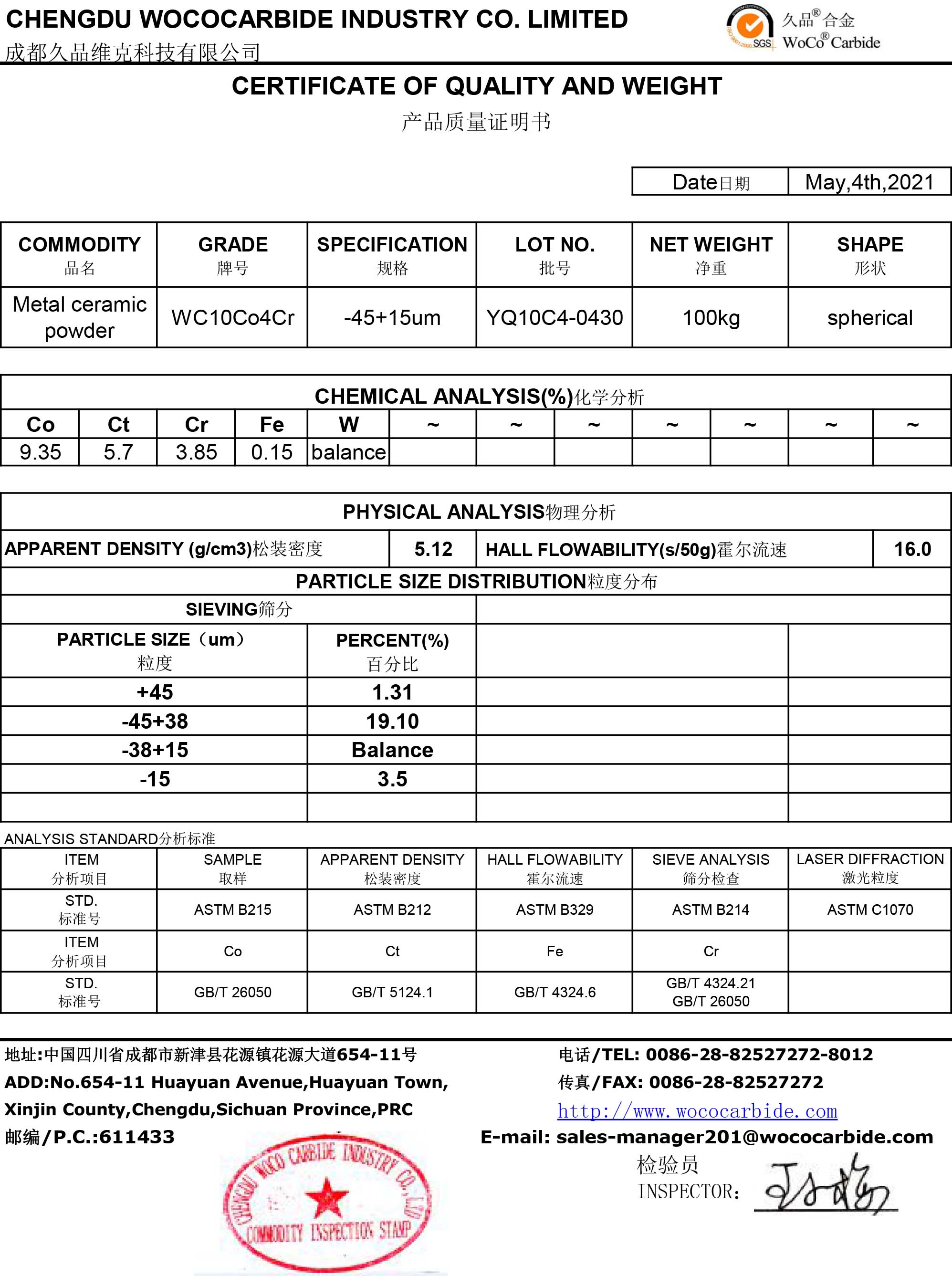

welding spray powder WC-10Co-4Cr (-25+15) spherical

Product Image

Details Image

Design Image

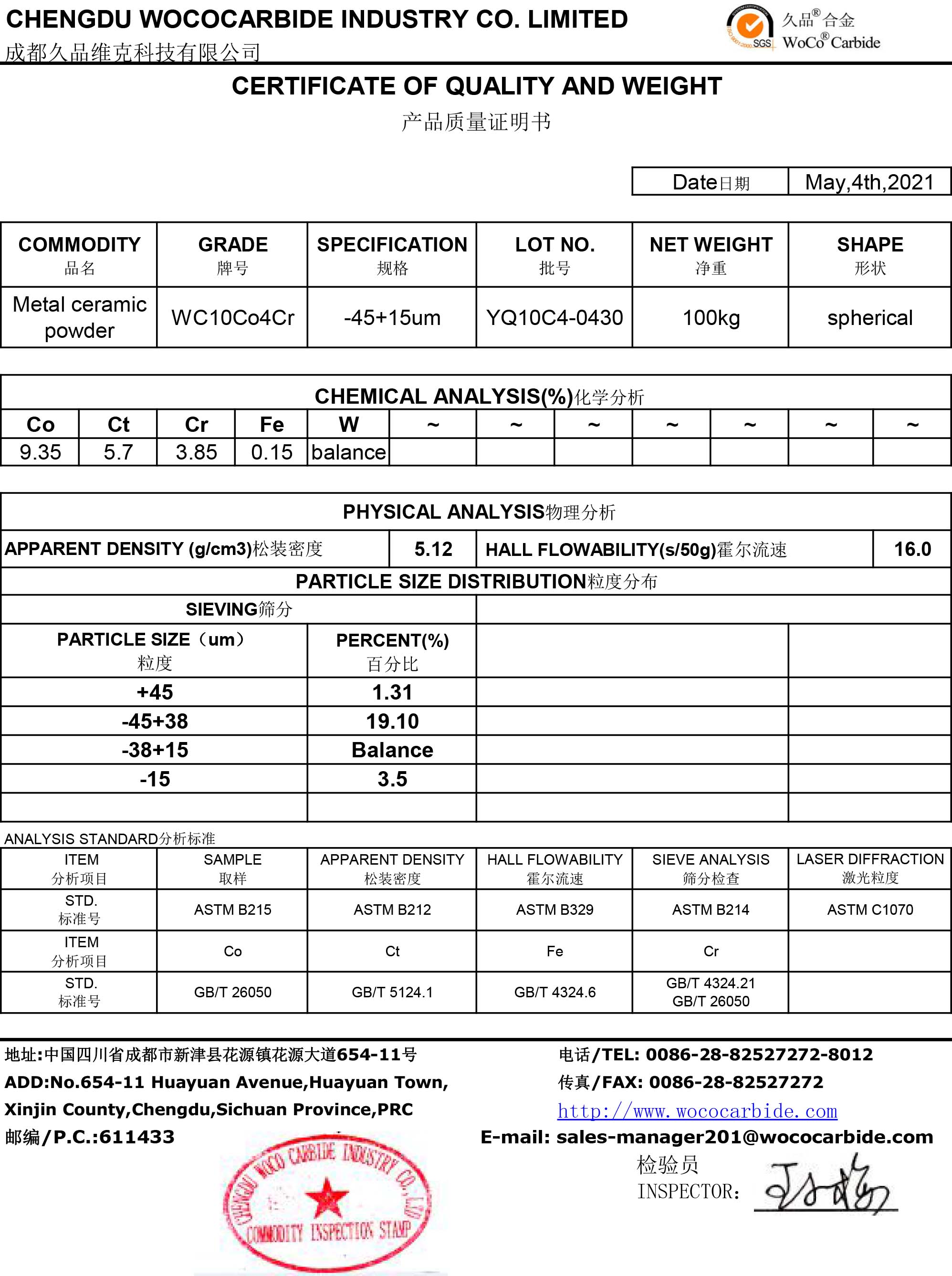

Composition

WC-10Co-4Cr (-25+15)

Performance Index

WC-10Co-4Cr (-25+15)

Packing Instructions

iron drum and carton

Description

Model: Wc-10Co4Cr

Color classification: 100g Wc-10Co4Cr powder 500g Wc-10Co4Cr powder 1000g Wc-10Co4Cr powder

Alloy composition: Wc-10Co4Cr

Production method: Atomization method

WC-Co coatings have high density, good erosion resistance and high bonding strength with the substrate. The coating is widely used in aerospace, metallurgy, machinery and other fields [1-2] to enhance the wear resistance of the base metal and the repair of worn parts. Introducing a certain amount of Cr into the WC-Co coating can not only improve the corrosion resistance of the coating, but also improve the erosion resistance of the coating.

Its composition is WC10Co4Cr, which is another important wear-resistant spraying material after WC12Co. Compared with WC12Co powder, WC10Co4Cr coating is not only resistant to wear, but also has certain corrosion resistance. When the working conditions are not only worn, but at the same time In the case of corrosion, WC10Co4Cr should be an option.

The inherent characteristics of WC-Co coating are wear resistance, erosion wear and fretting wear. The introduction of Cr element provides corrosion resistance. This type of material is a substitute for hard chromium plating. Under the situation of higher and higher requirements, hard chromium plating is declining, which has built a platform for the wide application of WC10Co4Cr. It is recommended to use supersonic flame spraying. The coating can produce compressive stress on the substrate, with high bonding strength, smooth and dense, hard and wear-resistant. Suitable for supersonic spraying, plasma spraying and other processes. An ideal substitute for hard chromium plating. The coating exhibits compressive stress, has good corrosion resistance, wear resistance and erosion resistance, and has a high surface finish. It is used in wet and corrosive environments, aircraft landing gears, papermaking processes, hydraulic cylinders and Valve industry.

Note: The content of alloy powder required for special workpieces can be customized according to customer requirements

Customized, under the guarantee of the ingredients required by customers, we will definitely guarantee the product quality.

To let customers buy at ease, with a comfortable concept, do their best for customers

Responsibility.

Hot recommended