- hot selling products

- buying lead

- selling lead

- Library

- Answer

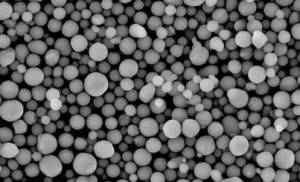

Stellite F Co Based Alloy Powder Plasma Surfacing Laser Cladding Powder Metallurgy Products

Product Image

Details Image

Design Image

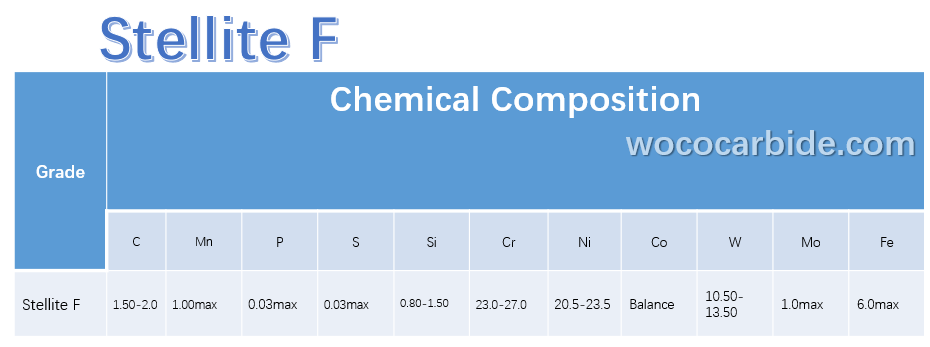

Composition

Performance Index

Packing Instructions

Description

Stellite F Co Based Alloy Powder is Co alloy powder with high content of W, so the hardness is high. The surfacing layer has good corrosion resistance, heat resistance and wear resistance, which can be maintained at 800 ℃.

Name: Stellite F cobalt based alloy powder

Standard: AWS a5013-rcocr-b

Application: used for the blade with strong abrasive wear, such as plastic, paper and chemical raw materials. Pre protection of blade edge and surfacing of valve sealing surface and exhaust valve cone of internal combustion engine. Stellite alloy castings are suitable for nuclear power, petrochemical, electric power, battery, glass, light industry, food and many other fields. It has the characteristics of wear resistance, corrosion resistance, oxidation resistance and high temperature resistance. Commonly used products are valve core, valve seat, shaft, shaft sleeve, pump parts, glass, battery mold, nozzle and cutting tool. Alloy categories are: Co based alloy casting, Ni based alloy casting, Fe based alloy casting. Stellite powder metallurgy products are made of Co based, Ni based or Fe based alloy atomized powder by pressing, sintering and finishing. The main products are valve stem, valve core (ball), valve seat, valve ring, sealing ring, wood saw tooth, bearing pump, bearing ball, etc.

Hardness: HRC ≥ 42

Weight: 5kg / bottle

Process: suitable for plasma powder surfacing process.

Note: if the alloy powder has moisture absorption, or the storage period is more than 3 months, it should be stored before use

Drying treatment (150 ℃ for 2 hours)

The cobalt based alloy powder produced by wococarbide is suitable for plasma surfacing, laser cladding and oxyacetylene spray welding. The cobalt base spray welding alloy powder described below is packaged in plastic bucket and iron bucket. However, due to the fine powder particles, it is easy to absorb moisture. It is recommended that the user should keep the temperature at 120 ℃ for two hours before use, and then use it after drying.

Hot recommended