- hot selling products

- buying lead

- selling lead

- Library

- Answer

High purity tungsten powder

Product Image

Details Image

Design Image

Composition

High purity tungsten powder

Performance Index

High purity tungsten powder

Packing Instructions

iron drum & carton

Description

1. Performance and standards of tungsten powder

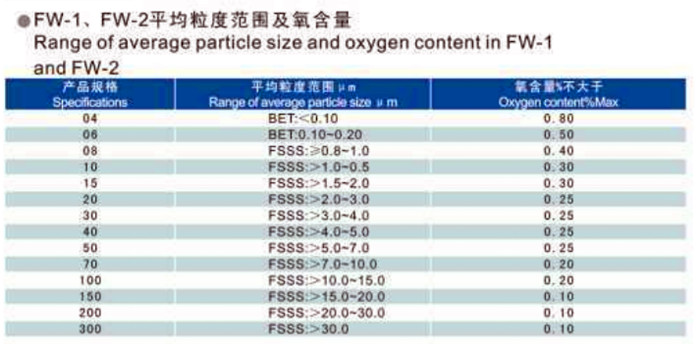

In addition to certain requirements for the content of impurities in tungsten powder, the oxygen content must be controlled within a certain range. The particle size of commonly used tungsten powder is generally Fisher's average particle size of 2-10μm. The tungsten powder has a polygonal particle shape. In addition, the specific surface, loose density, and tap density of tungsten powder also vary within a certain range. The properties of tungsten powder have a direct impact on the production of tungsten materials and the quality of cemented carbide, especially the impact of purity and particle size is more obvious. Tungsten powder is classified according to purity, particle size and different uses.

The earliest production of tungsten powder was to divide hydrogen-reduced tungsten powder into three levels according to chemical purity; Japan has formulated the industrial standard of "Tungsten Powder and Tungsten Carbide Powder" (JISH2116-1979); Britain, France, and the former Soviet Union have all established Unified national standards for tungsten powder. China’s industrial production of tungsten powder formulated the "Technical Conditions for Hydrogen Reduction of Tungsten Powder" (GB3458-82) in 1982. This standard specifies the performance and classification of tungsten powder. And the inspection methods, acceptance rules, packaging, transportation and storage items have all made clear regulations. For special-purpose and military-specific tungsten powder, the manufacturer can trial-produce it according to user requirements.

Second, the use of tungsten powder

Tungsten is mostly used in the production of cemented carbide and tungsten iron. Tungsten, chromium, molybdenum, and cobalt constitute a heat-resistant and wear-resistant alloy used to make cutting tools, metal surface hardening materials, gas turbine blades and combustion tubes. Tungsten is a refractory alloy with tantalum, niobium, molybdenum, etc. Tungsten copper and tungsten silver alloy are used as electrical contact materials. High-density tungsten nickel copper is used as a radiation shield. Metal tungsten wires, rods, sheets, etc. are used to make parts of light bulbs, electronic tubes, and electrodes for arc welding. Tungsten powder can be sintered into filters with various porosities. FW-1 is used as raw material for large slabs and tungsten rhenium galvanic couples. FW-2 is used for contact alloys and high specific gravity shielding materials. FWP-1 is used for spraying materials.

Tungsten powder is the main raw material for processing powder metallurgy tungsten products and tungsten alloys. Pure tungsten powder can be made into processed materials such as wires, rods, tubes, plates, and products with certain shapes. Tungsten powder mixed with other metal powders can be made into various tungsten alloys, such as tungsten-molybdenum alloy, tungsten rhenium alloy, tungsten-copper alloy and high-density tungsten alloy. Another important application of tungsten powder is to make tungsten carbide powder to make cemented carbide tools, such as turning tools, milling cutters, drill bits and molds; micron tungsten powder is used for surface hardening spraying;

Hot recommended