- hot selling products

- buying lead

- selling lead

- Library

- Answer

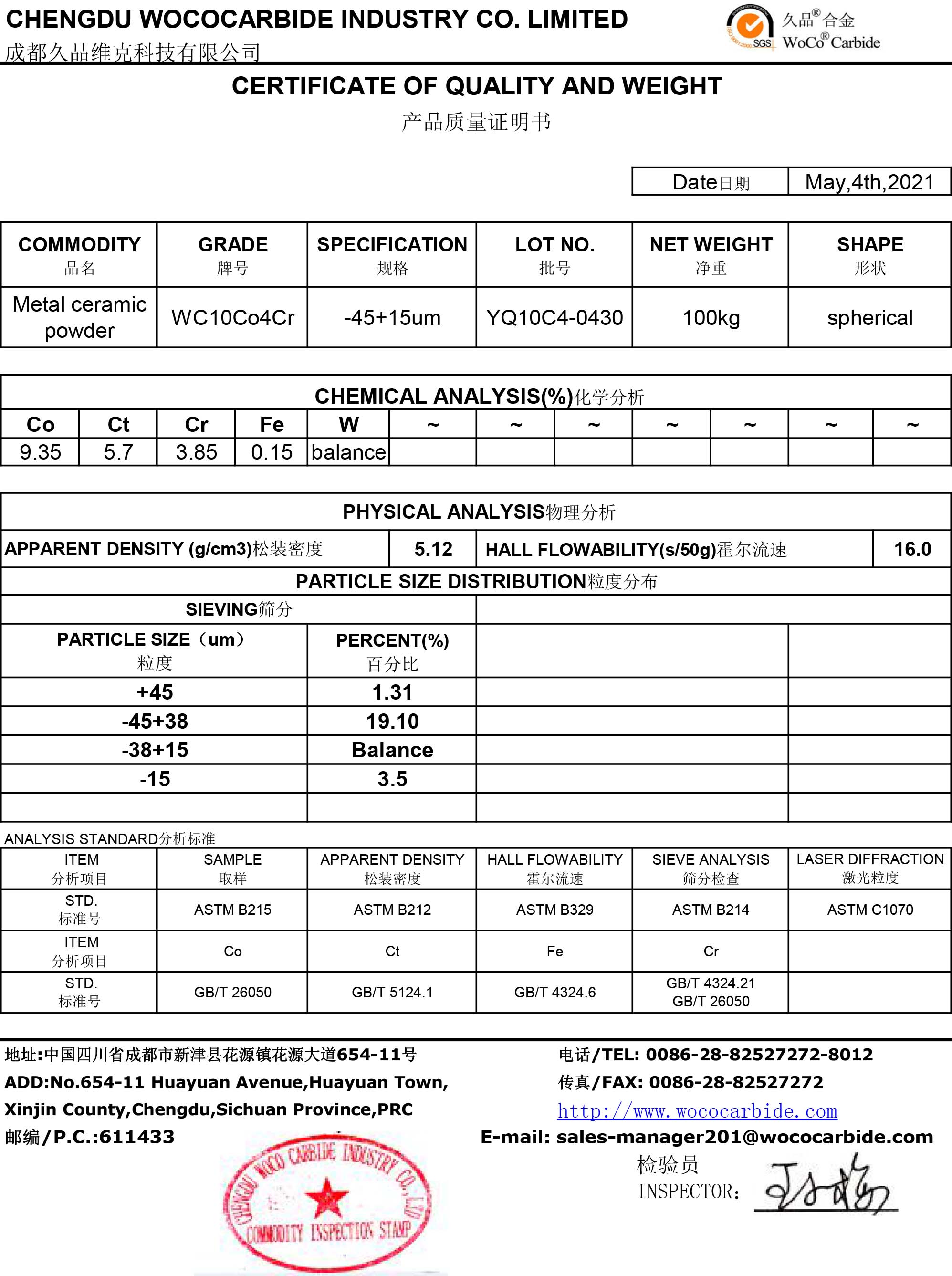

86WC10Co4Cr Woka 3652 15-45um

Product Image

Details Image

Design Image

Composition

86WC10Co4Cr Woka 3652 15-45um

Performance Index

86WC10Co4Cr Woka 3652 15-45um

Packing Instructions

iron drum and carton

Description

The HVOF supersonic spraying process and WC-10Co-4Cr powder are used to strengthen the surface of the working surface of the valve plate of the high-pressure gate valve. The experimental results show that the bonding strength of the coating reaches 72.63Mpa, and the bonding state between the coating and the substrate is good; the Vickers hardness value (HV0.3) of the coating is 1257.1, the microhardness value of the coating is uniform, and the coating is uniform. The density and toughness are good; the porosity of the coating is about 1.5%. Through the 100Mpa water pressure test, there is no leakage on the working surface of the valve plate, indicating that the coating is dense and meets the working needs of high-pressure gate valves at this porosity level.

Valves are widely used in various sectors of the national economy such as petroleum, chemical, metallurgy, electric power, textiles, light industry, machinery manufacturing, construction and national defense and military industries, and have become indispensable control equipment in various fluid devices. Gate valve refers to a valve in which the opening and closing body (valve plate) drives the sealing surface of the valve seat to move up and down by the valve stem, which can connect or cut off the fluid passage. Gate valves are usually suitable for working conditions that do not need to be opened and closed frequently and keep the gate fully open or fully closed. Compared with other types of valves, gate valves have the following advantages:

(1) Small fluid resistance;

(2) The external force required for opening and closing is small;

(3) The flow direction of the medium is not restricted;

(4) When fully open, the erosion of the sealing surface by the working medium is smaller than that of the stop valve;

(5) The body shape is relatively simple, and the casting process is better.

At the same time, the gate valve has the following shortcomings in the engineering application process:

(1) Both the external dimensions and opening height are relatively large. Large space required for installation;

(2) During the opening and closing process, there is relative friction between the sealing surfaces, which is easy to cause abrasion;

(3) Gate valves generally have two sealing surfaces, which makes machining, grinding and maintenance more difficult.

high pressure gate valve refers to the working medium is generally at room temperature or high temperature, and the pressure is very high, such as valves for oil field extraction and water injection. The working medium generally includes gas and liquid medium. Valves are generally defined according to the standards listed in Table 1.

Hot recommended