Category

- hot selling products

- buying lead

- selling lead

- Library

- Answer

WC-Co(83-17)NiSF RC 60 50-50

Product Image

Details Image

Design Image

Composition

WC-Co 83-17 Co 15.30-180%;Fe max.0.2%; Ctot 4.9-5.3%,W balance;Ni-SF RC60 Cr 14.2-16.5% Fe 3.5-4.5%,Si 4.0-4.8%,B3.0-4.9% C0.6-1.0% Ni balance.

Performance Index

WC-Co 83-17 63/32um Ni-SF RC 60 for both grain sizes

Packing Instructions

carton or iron drum

Description

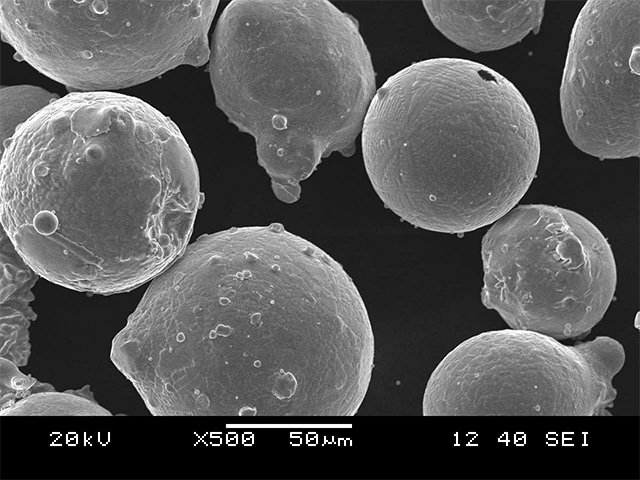

| high velocity oxygen-fuel ( hvof) spray | No.5 | Amperit560 (WC-Co(83-17)NiSF RC 60 50-50) | ||

| grade | Particle Size |

’ Amperit 560.077 63/32um ; Amperit 560.062 53/10um |

||

| ’WC-Co 83-17 Co 15.30-180%;Fe max.0.2%; Ctot 4.9-5.3%,W balance;Ni-SF RC60 Cr 14.2-16.5% Fe 3.5-4.5%,Si 4.0-4.8%,B3.0-4.9% C0.6-1.0% Ni balance. | Particle Size Available | WC-Co 83-17 63/32um Ni-SF RC 60 for both grain sizes | ||

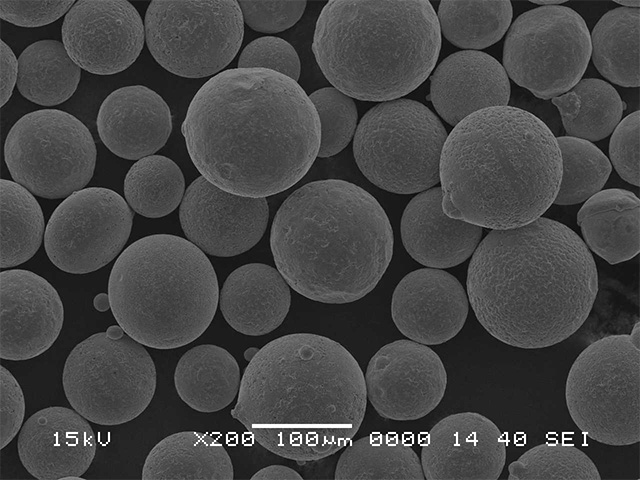

| spherical | Production Process | Gas atomization | ||

| WC-Co 83-17 63/32 3.8-4.4g/cm3;Ni-SF 3.8-4.6g/cm3; Ni-SF RC60 3.8-4.6g/cm3; WC-Co 83-17 53/10 um 3.8-4.4g/cm3 | Hall Flow | |||

| Grain Size | ||||

| Gas atomization | ||||

|

|

||||

| bottle,carton,iron drum | ||||

Hot recommended