A premise for the wide use of tungsten carbide is that the combination of carbon and tungsten can produce many unique and excellent properties, such as heat resistance, rust resistance, scratch resistance, corrosion resistance, hardness can be second only to diamond, and excellent electrical conductivity. At the same time, the overall strength can reach three times that of steel, and tungsten carbide is easy to form and can be processed into various shapes, or the alloy can be sprayed on the corresponding metal products by spraying with tungsten carbide.

Regarding tungsten carbide spraying, its application range is too broad, and it is involved in many places. Today, Huaian metal spraying manufacturers take you to know the five application fields of tungsten carbide spraying technology!

1. Carbide

For example, drilling platforms or mining platforms need a lot of cemented carbide. These are where tungsten carbide can play a big role. At present, about 65% of tungsten carbide in the world is used in mining drill bits or cutting materials. Some are alloys or stainless steels reinforced by tungsten carbide spraying.

2. Industrial alloys

More than 17% of tungsten carbide materials will be used to make various special alloys or composite materials. These cemented carbides can be combined with nickel, iron, silver and copper for applications in the construction industry, the electronics industry, the manufacture of industrial gears, radiation shielding materials and the manufacture of materials for the aerospace industry.

3. Rolling mill products

About 10% of tungsten carbide is also used to make various mill products, including various end mills and mill inserts. These products vary in size and shape depending on the material they come in contact with and machine, but all are used for grinding and milling. Because tungsten carbide is so hard and easy to mold, attachments can be created for precision milling applications, producing coarse-ground materials or the finest powders.

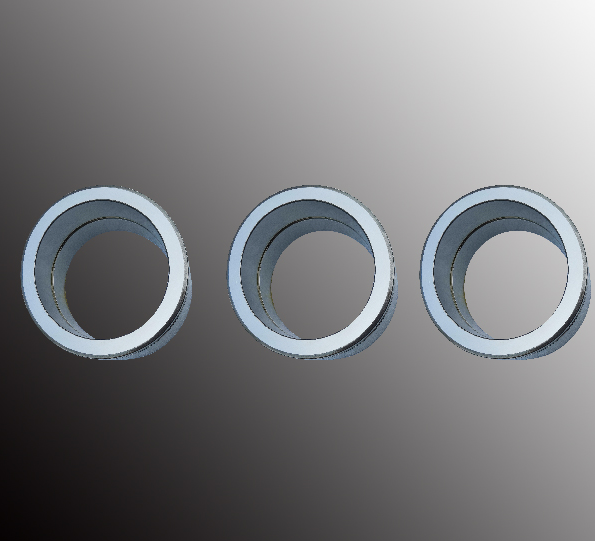

4. Jewelry

The above three application places have accounted for more than 90% of the annual application of tungsten carbide, but now tungsten carbide products have expanded into new fields, such as becoming more and more popular in the jewelry and jewelry industry. The hardness of tungsten carbide makes it suitable for making rings, pendants, earrings and some other metal parts of jewelry. When properly cut and polished, tungsten carbide is actually very beautiful and can partially replace gold jewelry products.

5. Surgical tools

At present, the medical industry is another important application field of tungsten carbide. Usually, the shank of various surgical knives is made of stainless steel or titanium alloy, and the blade part is generally made of tungsten carbide. Tungsten carbide has the characteristics of high hardness and wear resistance, which can effectively prolong the service life of surgical tools.

Of course, in addition to the above five applications, tungsten carbide also has good applications in other fields, such as ski poles, snowboards, fishing rods in the sports field, and the cutting and crushing parts of some recycling machines.

热门资讯