Tungsten, the 74th element in the periodic table, was early used as a filament in incandescent light bulbs, but otherwise, pure tungsten seems to be of little use, but its compound tungsten carbide has a wide range of applications, from tungsten carbide spraying to Tungsten carbide alloy, etc. Used in various occasions. So what is the difference between tungsten and tungsten carbide that will lead to a different range of applications? Today, Metal Spraying Company will explain it to you!

The obvious feature of tungsten is high temperature resistance. It is a metal with a high melting point, which can be as high as 3370 °C, and also has an ultra-high density, which can be as high as 19.25 g/cm 3 . But the disadvantages of tungsten are obvious, especially in the case of impure, low ductility, easy to break, and brittle at room temperature. Although pure tungsten is not fragile, pure tungsten is expensive. Except for some extremely demanding special occasions, people basically do not use pure tungsten.

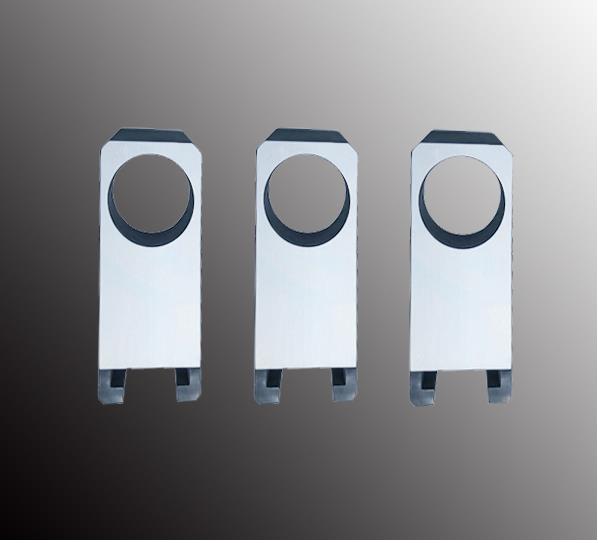

As a compound of metal tungsten, tungsten carbide is made by placing tungsten powder, carbon and hydrogen at a high temperature of 1400-1600 ° C. Its stiffness is 2-3 times that of steel, and its compressive strength is in First among all alloys.

In addition, tungsten carbide also has extremely high resistance to deformation, and can maintain its own stability under ultra-high temperature and high temperature.

When present in the form of a single carbon compound, tungsten carbide can rival the hardness of diamond and is known to be the hardest material.

Tungsten carbide's impact resistance, toughness and resistance to galling/scuffing/erosion are excellent, with a lifespan of 100 times that of steel under extreme conditions.

It is precisely because of these excellent properties of tungsten carbide that it can be widely used. These are some of the differences between tungsten and tungsten carbide.

热门资讯