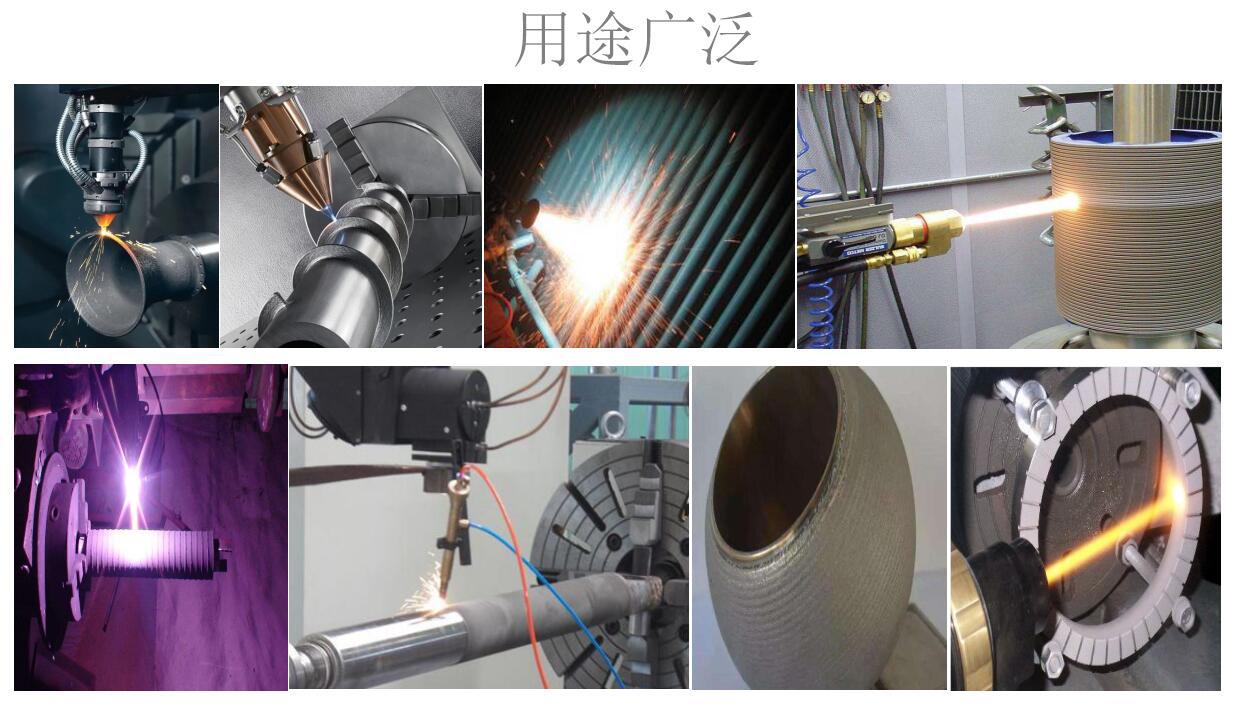

The application fields of thermal spray ceramic coating technology are very wide, mainly including:

1. Thermal barrier coating. The key components of aero-engines are superalloy turbine blades and turbine disks. These heated components are exposed to harsh environments such as high temperature, oxidation and high-speed air erosion. For gas turbine components that can withstand temperatures as high as 1100°C, which has exceeded the temperature limit (1075°C) used by nickel-based superalloys, the effective solution is to apply a high-melting-point ceramic coating with good thermal insulation, called thermal barrier coating. Thermal barrier coatings are mainly used for heating components of aviation, naval and land gas turbines, as well as civil internal combustion engines, turbocharged turbines, oxygen spray guns for metallurgical industry and other devices.

2. High-temperature adhesive and wear-resistant coating: heat treatment furnace rolls, back-up rolls, sintering furnace rolls and other high-temperature rolls are mostly operated at a high temperature of 800°C and 1200°C. Thermal spraying technology is used to spray special ceramic or cermet coatings on the surface of the high-temperature furnace roll. , It has good high temperature, anti-oxidation, anti-adhesion, anti-nodule and self-cleaning and purification functions, which can significantly increase the service life of the furnace roller, and can produce steel with excellent surface smoothness.

3. Wear-resistant and corrosion-resistant coating: The plunger of the high-pressure reciprocating metering pump used in chemical plants is sprayed with al203-tio2 composite coating instead of the traditional chrome plating process, and its service life is increased by 6 times. Under low-stress sliding wear and abrasion conditions, almost all original chrome-plated products can be replaced with thermal spray ceramic coatings. 4 Functional coating: Plasma sprayed supersonic sprayed superconducting ceramic coatings have been successfully applied. Superconducting ceramic coatings have shown good application prospects in magnetic shielding, microwave components, various types of transmitters, and quantum electronic devices. Spraying a 30um ratio3 coating on a 0.1mm iron sheet, its dielectric constant exceeds 6000, which has been widely used in ceramic chip capacitors. When the thickness of the al203 coating formed by plasma spraying is less than 1mm, it can withstand a voltage of over 2500°C at a high temperature of 1300°C, which meets the requirements of high-temperature electrical insulation. Spraying bioactive ceramics such as 50-75um hydroxyapatite on the titanium alloy substrate provides good chemical compatibility, so it can be used as an ideal artificial bone material. There are a lot of corrosion and wear problems in oilfield drilling and oil production engineering. It can be expected that thermal spraying technology and ceramic coating have a wide range of application prospects.

Hot information