The so-called 30º helix angle refers to the angle of the cutting edge of the tool, not the angle of the cooling hole. The hole spacing is the most suitable distance according to the tool design; the thread pitch is designed according to the actual requirements of the tool use, as shown in the figure: set the thread circumference as axis Y, thread pitch as X, thread angle α, tgα=Y/X; such as bar diameter D Φ10mm, blank tolerance 0.8-1.0mm; cooling hole diameter d is 1.4±0.2mm, hole spacing C is 4.8±0.2mm, blank helix angle α is 30°, tgα=0.57735, circumference=10*3.14=31.4

Pitch=31.4/0.57735=54.386. Tolerance range: the pitch should be 53.33-55.52mm. The spiral angle of the cooling hole should be between 17.355º-19.47ºmm. In the same way, the parameters of 45º, 15º double spiral hole rod can be proved.

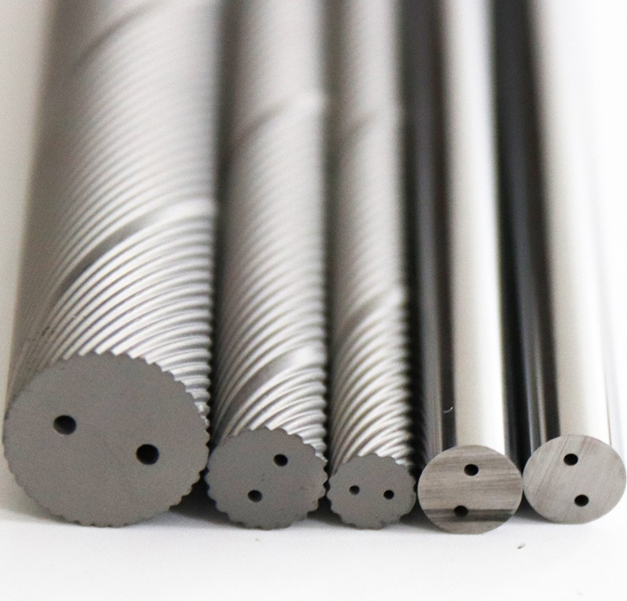

At present, there are two production technologies for double spiral hole rods in the world: external spiral extrusion and internal spiral extrusion.

The so-called external screw extrusion method is to use the female die with rib grooves in the mold design and manufacture to forcibly change the direction of the extruded fluid material and extrude the blank in a rotating manner; the cooling hole core rod is also manufactured The rotation direction of the rib groove of the mold is synchronized, and the entire process of extruding the blank is completed in a rotating manner; it should be noted that the rotation angle and direction of the rib groove of the mold die must be synchronized with the twist angle and direction of the core rod, otherwise, it will cause The geometrical parameters of the product are out of tolerance, and cooling hole deviation and hole cracks may even appear. This technology has more complex requirements for mold design, and the extrusion method is basically the same as the ordinary extrusion method; it is currently a kind of extrusion technology that is widely used at home and abroad.

The so-called internal screw extrusion method: is to use the special structure of the double screw extruder to extend the core rod to the extrusion screw, and use the screw to drive the core rod to rotate to achieve a spiral effect; the design of this process mold is relatively simple, but the extrusion Strict parameter requirements: the extrusion speed of the fluid during extrusion and the rotation speed of the core rod are in a fixed ratio, otherwise, the geometric parameters of the product will not meet the requirements; the fluid motion state of the entire extrusion process and the extrusion of other rods There is no difference between classes. Due to the difficulty of this technology, only Conner of Germany can produce it in the world.

There is no big difference between the three-spiral hole and the double-spiral hole in the extrusion method, but the core rod design of the mold is different.

Hot information