Carbon content control is the core of quality control in the cemented carbide production process. The relative magnetic saturation value is mainly used to measure the carbon in cemented carbide. Use chemical methods to measure the carbon content of cemented carbide, which needs to be destroyed

Specimen is a very complicated process with limited accuracy, which is difficult to achieve as a routine test item. The relative magnetic saturation is highly corresponding and sensitive to the carbon content of the cemented carbide. Without damaging the alloy, the carbon content in the alloy can be calculated quickly, simply and accurately, with good repeatability. With the development of science and technology, people are

The requirements for the accuracy of the carbon content are getting higher and higher. Therefore, the importance of using the relative magnetic saturation value of the cemented carbide to measure and control the carbon content in the cemented carbide is becoming more and more prominent.

1 Magnetization curve of WC-Co cemented carbide (M-H curve)

WC-Co cemented carbide contains ferromagnetic cobalt, so it has ferromagnetic magnetic properties.

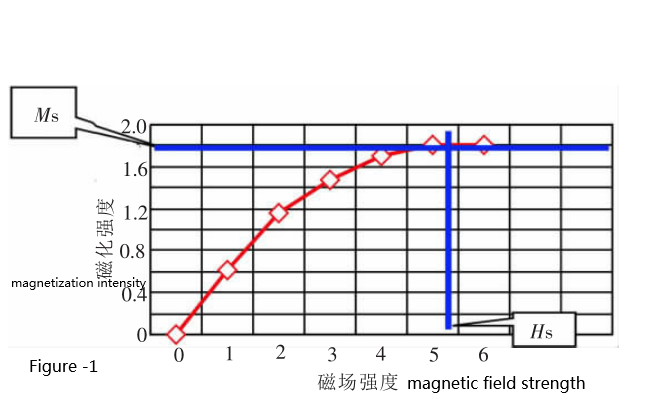

As shown in Figure 1, when the magnetic field intensity (H) gradually increases from zero, the magnetization (M) also gradually increases. When the magnetic field strength (H) increases but the magnetization (M) no longer increases, the magnetization (M) at this time is called the saturation magnetization (Ms), and the magnetic field strength (H) at this time is called the saturation magnetic field ( Hs). Because the WC-Co cemented carbide contains different cobalt content, different carbon content (different W in the γ phase), different added elements, different impurity elements, etc., they all constitute a specific cemented carbide, each specific grade WC-Co cemented carbide has its own specific MH magnetization curve. Assuming that the dissolved amount of other elements in the γ phase is constant except for W, the saturation magnetization Ms of the alloy decreases with the increase of the amount of W dissolved in the γ phase. For the same grade, we can draw various MH curves with different W contents, namely Various saturation magnetization Ms values of the same grade and different W content alloy can be measured.

Since the amount of W dissolved in the γ phase has a good corresponding relationship with the carbon content in the alloy, we can use the measured values of various saturation magnetization Ms of the same grade and different W content alloys to make the grade The relationship between the saturation magnetization and the carbon content of the alloy. In the WC+γ two-phase region, as the amount of carbon decreases, the amount of W dissolved in the γ phase increases, and the saturation magnetization decreases. In the WC+γ+η three-phase region, the solid solubility of tungsten in the γ phase remains unchanged at the lower limit of the two-phase region. Due to the decrease of carbon, part of the γ phase becomes the non-magnetic η phase, so the alloy's specific saturation magnetization decreases as the amount of carbon decreases.

Hot information