To undertake the above

Use of wear-resistant coating

Under various special working conditions (such as high temperature, low temperature, high altitude and heavy load, etc.), the performance of general grease cannot be adapted, and the metal surface wear-resistant coating can be used for lubrication.

Some structural parts and friction pairs cannot be continuously supplied with lubricating grease, installation work is not easy to access or loading and unloading is difficult, and regular maintenance cannot be performed, such as the support bearings of bridges. Metal surface wear-resistant coatings can be used for anti-wear lubrication.

The oil film of general lubricating grease can only bear a relatively small load. Once the load exceeds the limit it can bear, the oil film will break and the friction surface will seize. The wear-resistant coating on the metal surface can withstand an average load of 108pa or more.

Transmission parts in electronics, textiles, food, medicine, papermaking, printing and other machinery, transmission parts of cameras, video recorders, copiers, and many household appliances can be coated with EUBO metal surface wear-resistant coating treatment to improve the resistance of product parts Grinding ability.

Classification of wear-resistant coatings

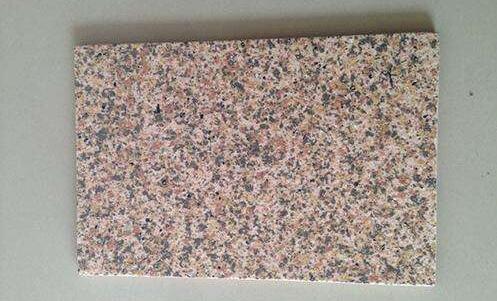

1. The wear-resistant coating formed by plasma spraying, arc spraying, flame spraying on the metal surface spraying ceramics, alloys, oxides, fluoroplastics, etc. is generally called thermal spraying wear-resistant coating.

2. Wear-resistant coating glue prepared with various resins, elastomers, etc., and the wear-resistant coating that is naturally or heated and cured after being applied to the metal surface is called chemically bonded wear-resistant coating.

Wear-resistant coatings can be divided into the following types:

(1) Adhesion resistant coating. Adhesive wear resistant coatings can be divided into soft support surface coatings and hard support surface coatings.

(2) Wear-resistant particle wear coating

(3) Fatigue and wear resistant coating

(4) Erosion resistant coating

Advantages of wear-resistant coating

1. It is composed of polymer materials, wear-resistant orthopedics, ultra-fine powder and inorganic polymer dispersion. After the coating is cured, the particles are tightly packed, with good adhesion, not easy to fall off, and good heat resistance.

2. Higher abrasion resistance experiments show that the wear resistance of the wear-resistant and waterproof coating is 10 times that of 16Mn steel, 9 times that of 65Mn steel, and 50 times that of refractory castables. With the increase of temperature, the resistance of the wear-resistant and waterproof coating Little change in grinding performance.

3. The wear-resistant coating has stable performance and uses special materials that are acid and alkali resistant, and it is not easy to react with the medium. Can be very resistant to environmental corrosion.

4. Specially made of fine resin, stable molecular structure, not easy to decompose due to aging.

Hot information