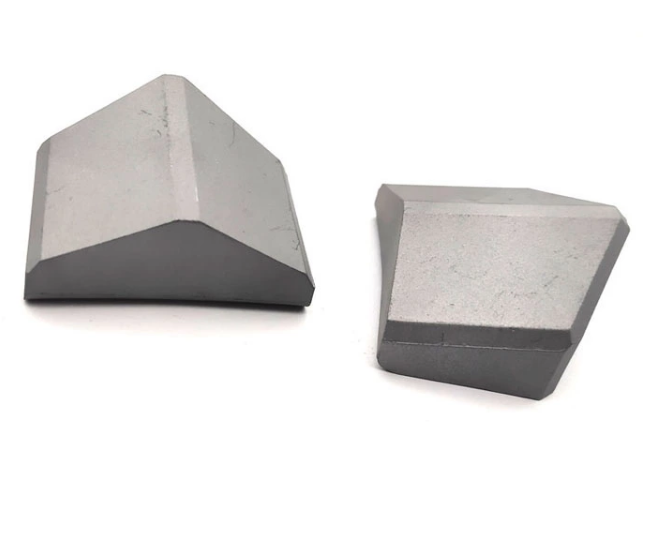

The scraper blade is the key part of the scraper to scrape the soil and protect the knife body from being worn. It is usually made of cemented carbide. The scraper of the shield tool is arranged with cemented carbide of different shapes and properties. Strength and wear resistance are the keys to improving tool life and efficiency.

(1) Choose high-performance WC-Co cemented carbide.

1)Using super coarse-grained cemented carbide. The coarser the WC grains and the higher the Co content, the better the toughness and fatigue strength of the tool and the higher the impact resistance. At present, the grain size of super coarse-grained cemented carbide WC has reached more than 7~8μm.

2) Using low pressure sintered cemented carbide to improve the uniformity of WC-Co alloy structure and reduce the porosity in the alloy structure.

3) Adding a small amount of TaC to WC-Co alloy can improve the high temperature strength and high temperature hardness of the alloy, and can improve the impact toughness and oxidation resistance of the alloy.

4) Using super-hard composite materials. Develop and prepare special cemented carbide and diamond composite blade materials for shield cutting tools, which are used in some key parts and particularly abrasive working conditions.

Hot information