1. Micro-morphology characterization

A cold field emission scanning electron microscope (SU8220, Hitachi High-Tech Co.) was used to analyze the microscopic morphology of the sample section.

2. Bubble point pressure test

After the hollow fiber ceramic membrane is completely wetted, due to the existence of interfacial tension, the gas needs different pressures to pass through the micropores of different pore diameters. The smaller the maximum pore diameter of the membrane, the greater the air pressure required to bulge the first bubble. The value is the bubble point pressure. The bubble point pressure can be used to characterize the maximum pore size of the hollow fiber ceramic membrane or whether there are obvious defects. The hollow fiber ceramic membrane closed at one end was soaked in deionized water for 12 hours, and then the air compressor was slowly turned on to press air from the other end. Stop the pressure increase when bubbles appear on the surface of the membrane, record the pressure at this time, and the air pressure is the bubble point pressure. Each film was measured 3 times and averaged.

3. Pure water flux test

A laboratory-made device is used to test the pure water flux, and pressure is applied from the outer tube wall of the membrane to make the pure water flow out of the inner tube wall of the membrane. Measure the effective membrane length and outer tube wall diameter of the hollow fiber ceramic membrane sample and convert it into the effective membrane area. The calculation formula of pure water flux is as follows:

Where: J is the membrane pure water flux, m3/(m2·h·MPa); V is the permeation volume of pure water, m3; P is the transmembrane pressure difference, MPa; A is the effective membrane area, m2; t is the permeation Time, h.

Where: J is the membrane pure water flux, m3/(m2·h·MPa); V is the permeation volume of pure water, m3; P is the transmembrane pressure difference, MPa; A is the effective membrane area, m2; t is the permeation Time, h.

4. Bending strength test

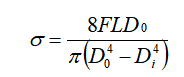

The U.S. Instron 5567 universal material testing machine was used to test the flexural strength of the hollow fiber ceramic membrane by the three-point bending method. The calculation formula is as follows:

In the formula: σ is the bending strength, Pa; F is the breaking load, N; L is the test span, m; D0 is the outer diameter of the membrane, m; Di is the inner diameter of the membrane, m.

Hot information