High-speed steel is an alloy tool steel composed of W, Cr, Mo and other alloy elements. It has high thermal stability, high strength and toughness, and a certain degree of hardness and wear resistance. Therefore, it is suitable for processing non-ferrous metals and Various metal materials, and because of the good processing technology of high-speed steel, are suitable for manufacturing complex forming tools, especially powder metallurgical high-speed steel, which has anisotropic mechanical properties, reduces quenching deformation, and is suitable for manufacturing precision and Complex forming tools.

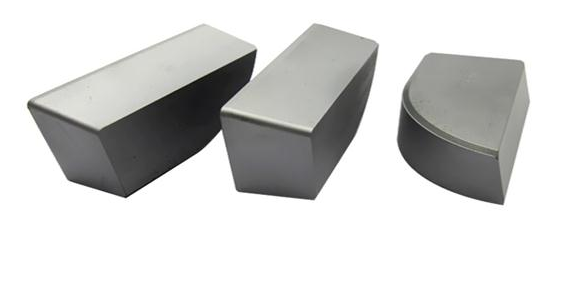

Cemented carbide inserts are the main cutting inserts today, with excellent performance and wide applications. However, the existing cemented carbide with abundant material resources has high hardness and wear resistance, better cutting performance than high-speed steel, and durability several to dozens of times that of high-speed steel, but its impact toughness is poor. Because of its excellent cutting performance, it is widely used as a tool material.

There are endless varieties of blades, and cubic boron nitride blades are one of them.

Both cemented carbide blades and cubic boron nitride blades are manufactured by powder metallurgy, and both have high hardness, high wear resistance, and good thermal stability.

Hard alloy blades are used to cut heat-resistant steel, stainless steel, high manganese steel, tool steel, etc. Cubic boron nitride blades are mainly used in the cutting of gray cast iron, wear-resistant cast iron, and various high-hardness materials. Although the hardness of cubic boron nitride blades is higher than that of cemented carbide blades, but also because of this, its brittleness is greater, the strength and toughness are poor, and it is not suitable for discontinuous surface processing under impact load. In addition, when using it to process soft iron group element materials, it is easy to produce long chips, scratch the rake face of the blade and form a built-up edge, which will cause the fluctuation of the cutting force and damage the blade.

Cemented carbide blades and cubic boron nitride blades have their own advantages and disadvantages. According to specific processing requirements, choose the appropriate blade to improve processing quality and processing efficiency.

Hot information