current position:Information and data>Characteristics of plasma arc surfacing

Characteristics of plasma arc surfacing

Compared with other surface surfacing methods such as oxyacetylene flame surfacing and electrode arc surfacing, plasma surfacing has many advantages.

1: High productivity. The plasma arc surfacing process is carried out under automatic control. Its productivity is high and the deposition rate is high. The current high-power plasma arc surfacing welding current is as high as 500A, and the deposition rate can reach 12kg/h.

2: The dilution rate of the base metal to the alloy is low. Due to the many adjustable specification parameters in the process, the heat input can be actively controlled. The alloy powder is pre-heated in the arc column and transitions to the molten pool in a spray shape, which buffers the arc blowing force. Function, the molten pool is heated evenly, so the penetration depth of the base metal can be controlled and the dilution rate of the base metal to the alloy can be reduced.

3: The surfacing layer is well formed. Plasma arc surfacing generally adopts argon protection, and the surfacing layer is formed flat and smooth. By changing the process specification parameters, the forming size can be accurately controlled and the size range is wide.

4: The spray welding layer has good quality and process stability. Due to the good stability of the plasma arc, the interference of external factors has little effect on the electrical parameters and arc stability, so that the process is easy to stabilize. Due to the high plasma arc temperature, concentrated heat, high spray welding speed, and one-time melting, the heat affected zone of the workpiece is small, the alloy structure of the spray welding layer is fine, the hardness and chemical composition are uniform, and the quality of the spray welding layer is good.

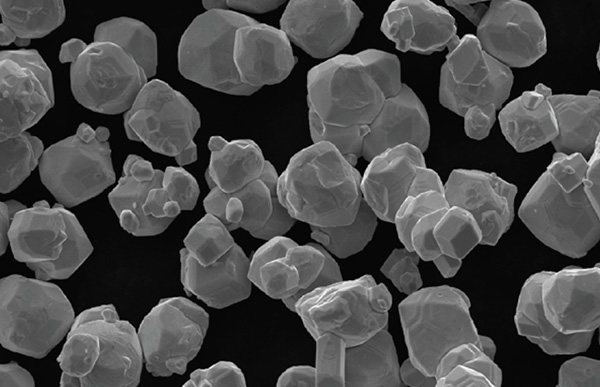

5: The alloy powder is easy to prepare and has a wide range of materials. The temperature of the plasma arc zone is as high as (1.0-5.0)×l0K, so various metals can be surfacing. The alloy powder for surfacing welding is directly atomized into spherical powder after smelting. It is easy to prepare and can be smelted into alloy powders with different compositions according to the required formula to obtain alloy welding layers with different properties to adapt to the surface properties of parts under different conditions. Requirements. There are many types of spray welding alloy materials, including cobalt-based, nickel-based, iron-based, and copper-based. Generally, alloys with high hardness, abrasion resistance, high temperature resistance and corrosion resistance are difficult to be made into wires and used for surfacing welding by other processes. However, it is simple and easy to use plasma spray welding to make these alloys into powder.

6: Good controllability. The arc parameters such as the atmosphere and temperature of the plasma arc can be adjusted by changing the power, the type of gas, the flow rate and the structure size of the nozzle, so as to realize automated production.

7: The temperature of the surfacing workpiece is relatively low, and it is generally not easy to deform. In order to further reduce the temperature of the workpiece during surfacing, gas can also be used to cool the workpiece.

Hot information