current position:Information and data>Post treatment of thermal spraying coating

Sometimes the coating obtained by spraying cannot be used directly, and a series of post-treatments are necessary. Coating for anti-corrosion In order to prevent corrosive medium from reaching the substrate through the pores of the coating and causing corrosion of the substrate, the coating must be sealed. There are many materials used as sealing agent, but it should be considered according to various factors such as the working medium, environment, temperature and cost of the workpiece.

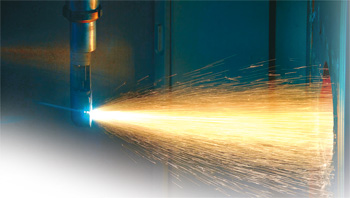

For workpieces subjected to high stress load or impact wear, in order to improve the bonding strength of the coating, the sprayed layer must be remelted (such as flame remelting, induction remelting, laser remelting, hot isostatic pressing, etc.) to make it porous The coating that is only mechanically bonded to the substrate becomes a dense coating that is metallurgically bonded to the substrate. If the dimensional accuracy is required, the coating must be mechanically processed.

Hot information