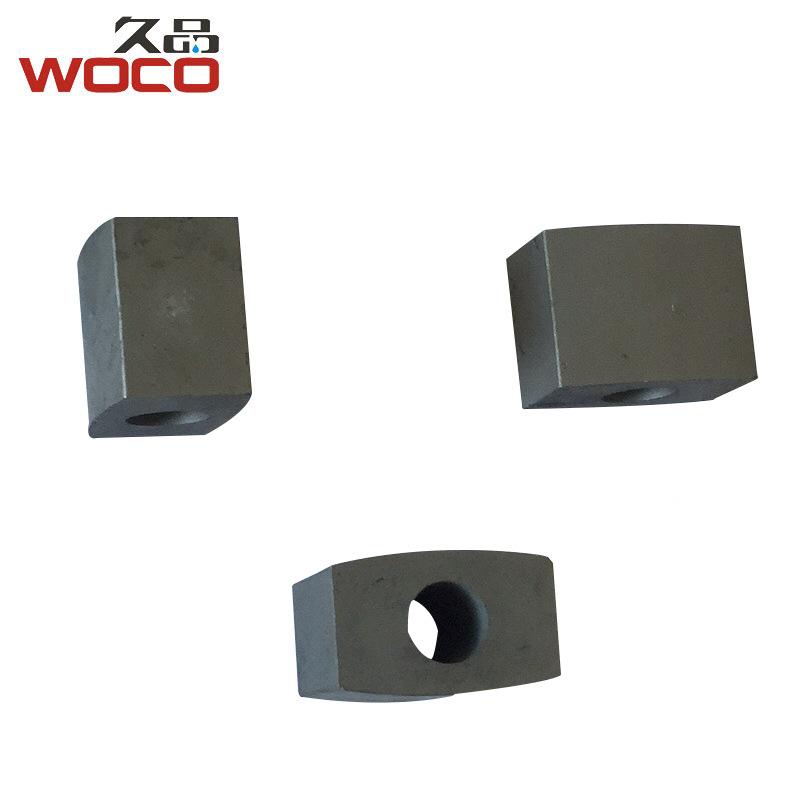

Let me talk about the sparks of the tungsten steel conductive block. The most likely cause of the sparks of the tungsten steel conductive block is that the conductive is worn out. You can change the surface or position. Another possibility is that the tungsten steel conductive block is installed too low, so that the molybdenum wire seems to be in contact and non-contact. Just adjust the tungsten steel conductive block upward to ensure good contact.

In addition, pay attention to the quality of the tungsten steel conductive block. Generally, the tungsten steel conductive block is hard alloy wear-resistant, but once the discharge starts, it will go down soon.

Let’s talk about short circuits. If the molybdenum wire and the workpiece are frequently short-circuited during processing, it means that the tracking is too fast. If the adjustment does not work, then look at the water concentration. If it doesn't work, there is a problem with the tracking circuit and needs repair. This is the case for the cut workpiece, because it is difficult for water to enter the processing point. In this case, the key is to ensure that the water entering the processing point is more effective than adjustment. The pulse width does not need to be special, just follow your usual, such as 50-60; the pulse interval should be large, so let it be 10 or more. In addition, a little vibration of the guide wheel will widen the cutting seam, and the processing state will be better. Haha, the cutting fluid has a better drainage effect. This may be related to the direction of flushing. When the molybdenum wire goes down, the water is cut into the slit by the molybdenum ribbon, so the discharge state is good; when the molybdenum wire goes up, the flushing is not good, and the internal discharge is in a dry discharge state. It will be fast and slow. Focus on adjusting the flush. In addition, when the silk barrel is on the left and on the right, try the tension of the silk to check whether there is any loose silk on one side.

Hot information