1. Phase structure of aluminum coating

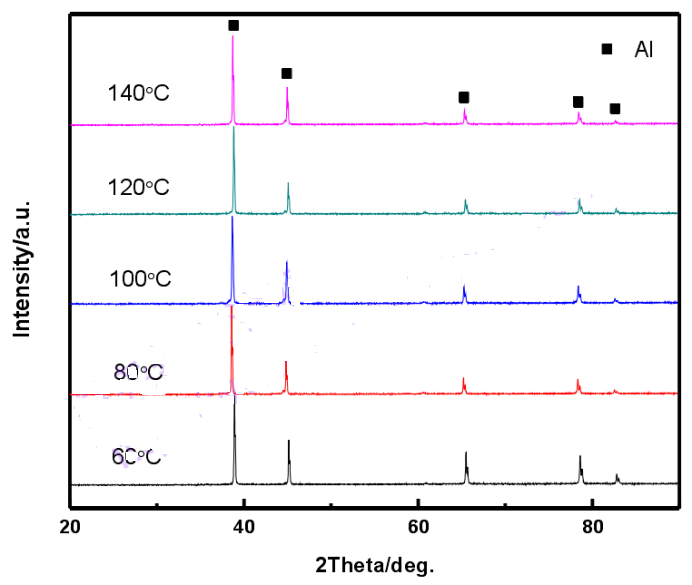

Figure 1 shows the X-ray diffraction patterns of aluminum coatings prepared by spraying on the surface of NdFeB magnets at different preheating temperatures. It can be seen from Figure 4-1 that when the preheating temperature is 60C, 80C, 100C, 120C and 140C, the XRD pattern of the aluminum coating only has the diffraction peak of A1, and no other diffraction peaks appear. The aluminum coating is a surface It is composed of Al phase with centered cubic crystal structure.

Figure 1 XRD patterns of aluminum coatings prepared at different preheating temperatures

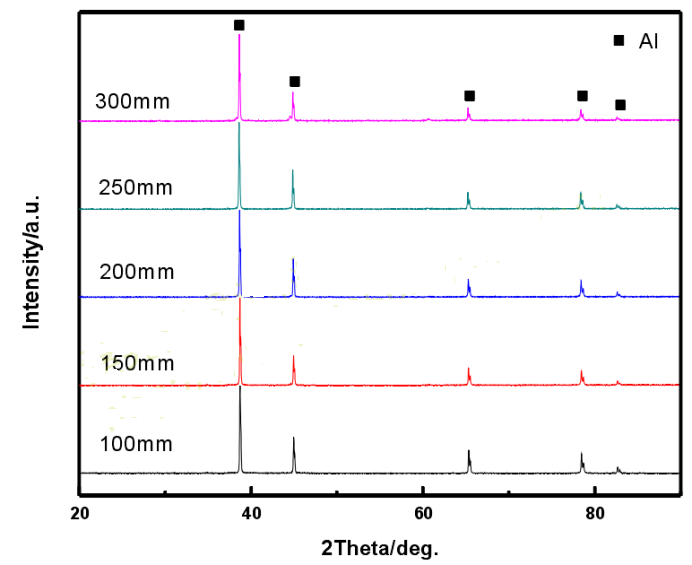

Figure 2 shows the X-ray diffraction patterns of aluminum coatings prepared at different spraying distances. It can be seen from Figure 4-2 that when the spraying distance is 100mm, 150mm, 200mm, 250mm and 300mm, only the diffraction peak of A1 exists in the XRD diffraction pattern of the aluminum coating, which is different from that of the aluminum coating at the preheating temperature. The XRD patterns are consistent, no other diffraction peaks appear, and the aluminum coating is still composed of Al phase with a face-centered cubic crystal structure.

Figure 2 XRD patterns of aluminum coatings prepared under different spraying distances

2. Surface morphology of aluminum coating

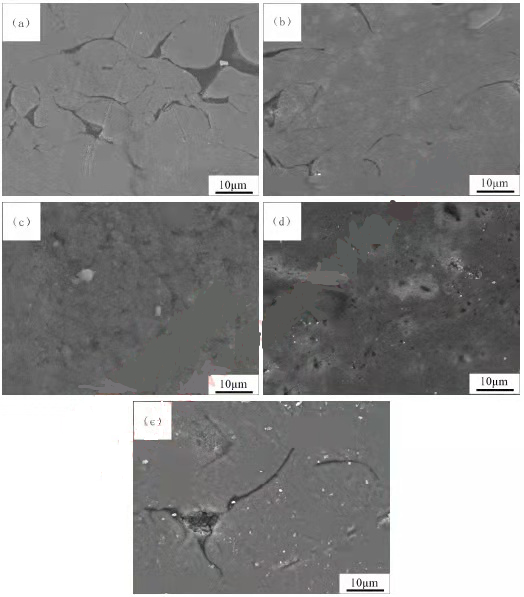

Figure 3 shows the surface morphology of aluminum coatings at different preheating temperatures. When the preheating temperature is 60C, there are many holes on the surface of the aluminum coating, and the structure is loose, resulting in a decrease in the compactness of the aluminum coating; as the preheating temperature rises to 80C, the pores on the surface of the aluminum coating begin to decrease. However, there are still large pores in the edge area of the aluminum coating, which adversely affects the compactness of the aluminum coating; as the preheating temperature rises to 100C, the pores on the surface of the aluminum coating decrease, and only small pores exist. The pores are obviously reduced, the structure is tight, and there are no too large pores, which is beneficial to improve the compactness of the aluminum coating. As the preheating temperature continued to increase to 120C, the pores on the coating surface increased significantly, and no larger pore defects appeared. When the preheating temperature is 140C, the pores on the surface of the coating become larger, and cracks appear on the surface of the coating, which reduces the compactness of the aluminum coating. From the above analysis, it is concluded that when the preheating temperature is 100°C, the aluminum coating on the surface of the NdFeB magnet has fewer pores, no obvious cracks, and the coating density is improved.

Figure 3 Surface morphology of aluminum coatings prepared at different preheating temperatures: (a) 60°C; (b) 80°C; (c) 100°C; (d) 120°C; (c) 140°C

Figure 3 Surface morphology of aluminum coatings prepared at different preheating temperatures: (a) 60°C; (b) 80°C; (c) 100°C; (d) 120°C; (c) 140°C

Hot information