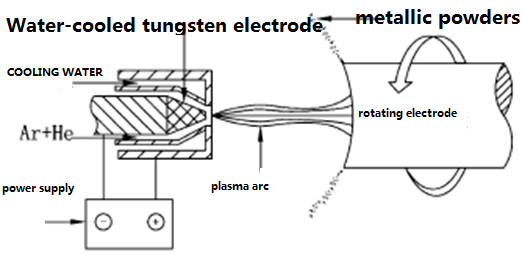

(3D printed titanium alloy parts) Cobalt-chromium alloys are commonly used in surgical implants such as alloy artificial joints, knee joints and hip joints due to their high wear resistance, good biocompatibility, and nickel-free (nickel content <0.1%), as well as engine parts , Wind turbines and many other industrial components. Aluminum alloy is the most widely used non-ferrous metal structural material in the industry. It has low density, high specific strength, close to or exceeds high-quality steel, and good plasticity. Studies have shown that aluminum alloys for 3D printing can achieve dense parts, fine structures, and mechanical properties comparable to castings or even better than casting molded parts. Compared with traditional process parts, their quality can be reduced by 22%, but the cost can be reduced by 30%. %. Copper alloys have excellent thermal and electrical conductivity. Copper with excellent thermal conductivity in thermal management applications can combine design freedom to produce complex internal structures and conformal cooling channels. (2) How are the metal powders used for 3D printing made? The metal powder preparation method can be divided into: reduction method, electrolysis method, grinding method, atomization method, etc. according to the preparation process. At present, the two most advanced powder making processes commonly used in China are the argon atomization method and the plasma rotating electrode method. 1. Argon atomization method The argon atomization method is a pulverizing method that uses fast-flowing argon gas to impact metal liquid, break it into fine particles, and then condense into solid powder. 2. Plasma rotating electrode method

Hot information