current position:Information and data>The role of manganese powder

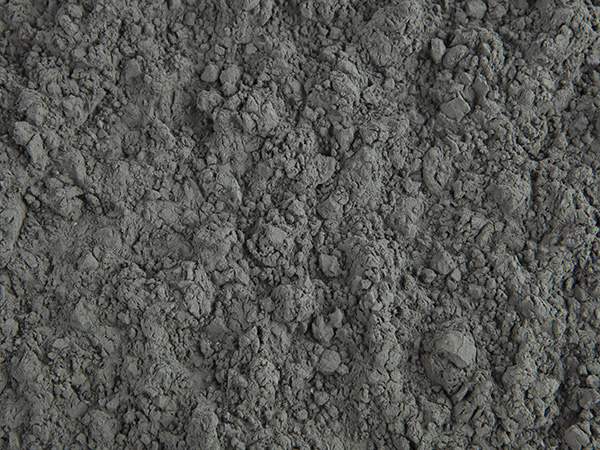

The role of manganese powder

Electrolytic metal manganese is the main material for manufacturing trimanganese tetroxide. In addition, due to its high purity and low impurities, it is an important alloy element for the production of stainless steel, high-strength low-alloy steel, aluminum-manganese alloy, copper-manganese alloy, etc., and it is also an electrode and ferrite. Permanent magnet alloy elements, and many indispensable raw materials in the production of manganese salts for pharmaceuticals and chemicals; newly developed vibration-damping alloys also require electrolytic metal manganese.

In recent years, the world's aluminum industry has become the main user of electrolytic metal manganeseIn the iron and steel industry, electrolytic metal manganese is also used as a deoxidizer and desulfurizer.

According to statistics, the average consumption of electrolytic manganese per ton of steel is 0.06kg.

With the progress of metallurgical technology, high-efficiency steel and jet metallurgy technology have been greatly developed. The application of electrolytic metal manganese powder in the metallurgical industry has been increasing, and the amount has been expanded, breaking the above indicators.

In recent years, due to the rapid development of special steel, especially the development of my country's 200 series stainless steel, the proportion of metal manganese in metallurgy has become larger and larger.

Aluminum-manganese alloy is a modern light and beautiful building material, decoration engineering material and anti-corrosion support material for underground engineering.

In China in recent years, aluminum-manganese alloy doors and windows have gradually entered ordinary residential houses, greatly expanding the market for metallic manganese.

Electrolytic manganese metal production process: Electrolytic manganese metal is a hydrometallurgical product of manganese. In the domestic production practice for many years, the production process of "leaching-purification-electrolysis" is generally adopted.

The main method is to use manganese carbonate powder and inorganic acid to react to prepare manganese salt solution, add ammonium salt as a buffer, add oxidizing agent to neutralize iron, add vulcanizing agent to remove heavy metals, and go through "sedimentation-filtration-depth"

Purification-filtration" produces pure manganese sulfate solution. After adding additives, it enters the electrolytic cell as an electrolyte for electrolysis to produce metallic manganese.

mainly is used in diamond tools, powder metallurgy and other industries.

Hot information