current position:Information and data>Introduction of supersonic flame spraying process

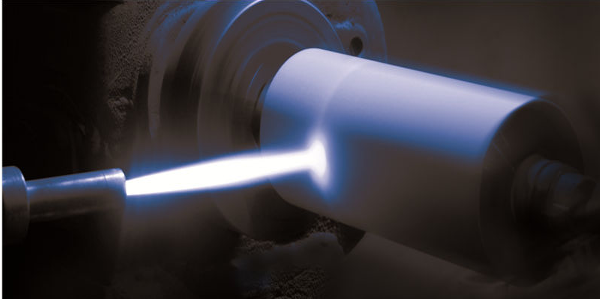

Supersonic flame spraying is a new type of thermal spraying technology invented in 1981 by Browning in the US. The core of supersonic flame spraying (HY0F) equipment

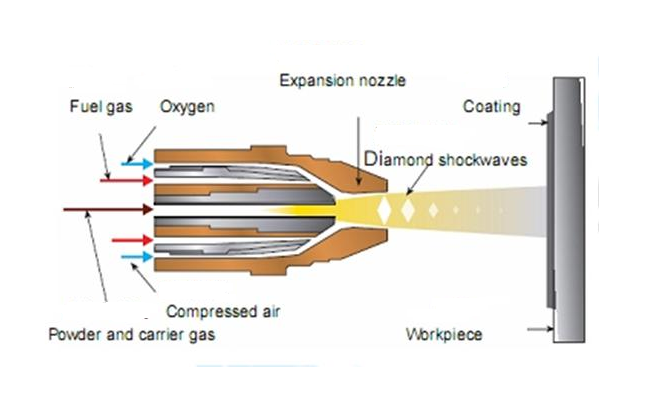

Combustion chamber (enable the spray material particles to be fully heated and accelerated), Laval nozzle (accelerate the flame flow to supersonic speed) and the constant cross-section long nozzle (make the spray material particles

Acceleration) consists of three parts. Its working principle is as follows: the liquid that enters the combustion chamber through the small holes is burned, such as kerosene, which is ignited after being atomized and mixed with oxygen, and a strong

Therefore, the heat energy released by combustion causes the product to expand violently. When the expanded gas flows through the Laval nozzle, it is subjected to the beam of the nozzle to form a supersonic high-temperature flame stream. This flame flow adds

Material to the surface of the substrate to form a high-quality coating.

Supersonic flame spraying principle diagram

Features of supersonic flame spraying

1. The flame velocity is high but the temperature is relatively low, suitable for spraying carbide-containing materials.

2. The coating is dense and the surface roughness is low.

3. The bonding strength is slightly lower than that of explosive spraying, reaching more than 70MPa.

4. The spraying efficiency is high, but the fuel consumption is large, and the spraying cost is relatively high.

5. Loud noise (>120aB), sound insulation and protective devices are required.

Commonly used materials for supersonic flame spraying

Hot information