1. The welding tool should have sufficient rigidity,

It is mainly reflected in the maximum allowable size of the tool holder, and the use of high-strength steel and heat treatment;

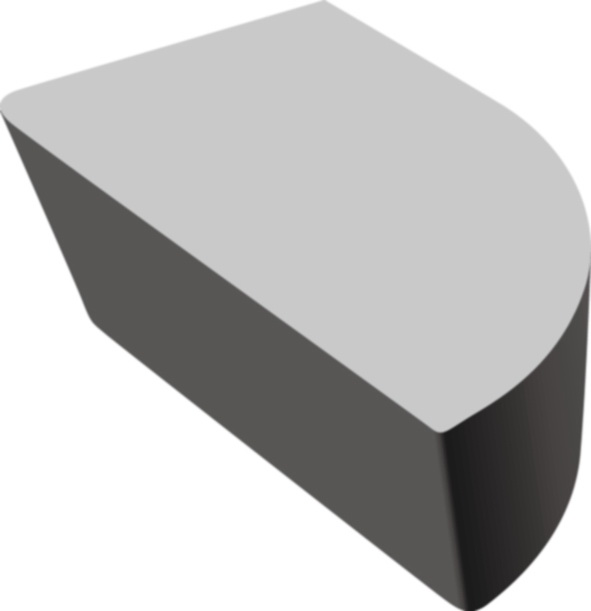

2. The cemented carbide blade should be fixed firmly;

The welding blade is connected to the shank by welding. The surface of the blade and the shank need to be cleaned before welding to ensure that the welding is firm and free of impurities; the blade needs to be inspected before welding. Surface carburization and bending are not allowed. Ensure the maximum contact between the blade and the welding surface of the tool holder;

3. Choose the right solder;

During the soldering process, the solder should ensure good wettability and fluidity, and eliminate bubbles, and the solder should be in full contact with the alloy soldering part, and there should be no shortage of solder;

4. Insulation after welding;

Since the shrinkage coefficient of cemented carbide is different from that of steel, the blades need to be slowly cooled in an incubator or under the protection of insulation materials after high-temperature welding to eliminate stress and ensure that the performance of the alloy is not affected;

5. Choose a reasonable process for sharpening:

Due to the brittleness of cemented carbide blades, it is easy to crack in the case of rapid cold and rapid heat. Therefore, a reasonable process is required when grinding cemented carbide blades, and rapid cooling is avoided;

6. When installing the tool, the length of the blade extending from the tool holder should be as small as possible to avoid vibration of the tool, resulting in lack of machining accuracy and abnormal damage of the carbide blade;

7. After the cemented carbide tool is used to achieve normal blunt grinding, it must be ground. After grinding, it is necessary to grind the cutting edge and the corner of the tool tip with oilstone, so as to improve the service life and safety and reliability of the cemented carbide tool;

Hot information