current position:Information and data>Nickel-based tungsten carbide alloy hammer

Nickel-based tungsten carbide alloy hammer

Nickel-based tungsten carbide alloy hammer

The alloy hammer adopts the "thermosetting coating" cladding method to prepare different content of WC reinforced Ni60A alloy composite coating on the low carbon steel hammer substrate. The hardness and wear resistance of the coating increase with the increase of WC content. When the WC content reaches 50%, the content of WC added to the Ni-based alloy reaches an appropriate ratio, and the wear resistance is better. The relative wear resistance is Ni60A coating. 6.5 times the layer; the coating is metallurgically combined with the hammer substrate.

Technical parameters of bimetal multi-layer wear-resistant composite board

Technical parameters of bimetallic multi-layer wear-resistant composite board

1. Technical parameters of wear-resistant steel plate:

1. Hardness HRC

Wear-resistant layer thickness ≤ 4mm: HRC54-58;

Wear layer thickness>4mm: HRC56-62

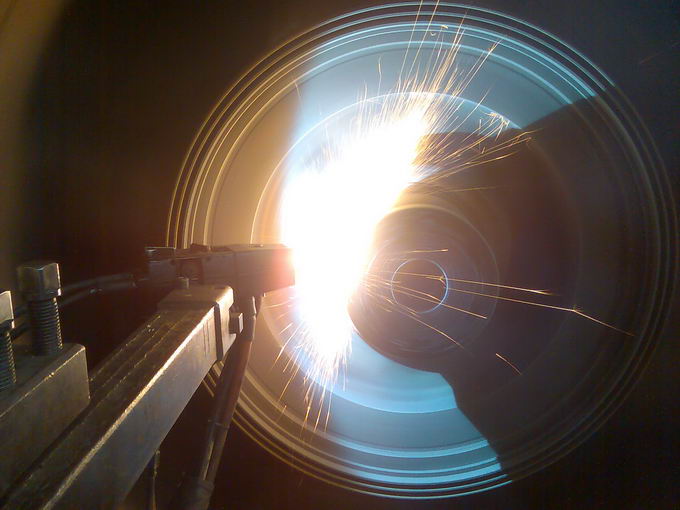

Gas shielded flux-cored wire surfacing process parameters

Gas shielded flux-cored wire surfacing process parameters

Electric current: generally: 150~350 amperes, common specification: 200~300 amperes

Voltage: general range: 22~40 volts, common specification is: 26~32 volts

Dry elongation: The length of the welding wire from the front end of the contact tip, which is generally 10-15 times the diameter of the welding wire, that is, 15mm-25mm long.

Welding speed: the length of the weld seam per minute, 300-500 mm per minute for single-pass welding; individually up to 2500 mm/min (such as pick welding); for swing welding, 120-200 mm/min.

Hot information