current position:Information and data>Tungsten alloy aviation and military applications

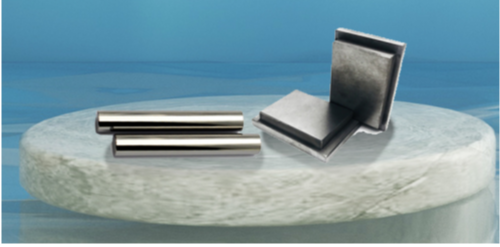

Tungsten alloy products are one of the main products of wococarbide.com. They are non-standard and customized. We especially support customized drawings and samples because we have advanced processing equipment and strong processing capabilities. Tungsten alloys are used as nozzles, gas rudders, air rudders, and nose cones of missiles and rocket engines in aerospace. The main requirements are high temperature resistance (3000K~5000K) and high temperature resistance to air erosion. Copper is mainly used to volatilize at high temperatures. The formed sweat cooling effect (copper melting point 1083°C) reduces the surface temperature of tungsten copper and ensures the use under extreme high temperature conditions.

Tungsten alloy is a very, very important material in military industry. Whether it is artillery, shells, armor, without tungsten alloy, now it is difficult to move. The melting point of tungsten alloy is very high, the hardness is much stronger than that of alloy steel, the toughness is also better, of course, the density is also greater. To put it simply, the 88mm gun of the German "Tiger" tank in World War II used tungsten core armor piercing projectiles, which was 20% more powerful than steel core armor piercing projectiles. However, because tungsten sand is very scarce, there are usually only a dozen tungsten core armor-piercing bullets in the "tiger" type with more than 90 bullets. The same situation is true for the Soviets. The Soviet version of the T-72 tank uses tungsten core armor-piercing shells, and the artillery is quite powerful.

Hot information