current position:Information and data>How to choose the thermal spraying process

When choosing a thermal spraying process, we need to choose the corresponding thermal spraying process according to different application conditions, environments and requirements.

The process selection of thermal spraying should follow the following principles:

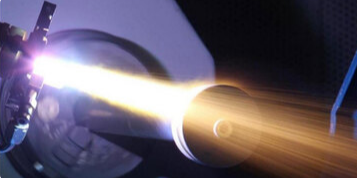

(1) For metal spraying construction with a large amount of engineering, arc spraying should be used. The binding force of the coating is not high, and the melting point of the spraying material does not exceed 2500 °C. Flame spraying with low equipment cost can be used.

(2) For large batches of workpieces, automatic spraying should be used;

(3) Supersonic spraying can be used for metal or alloy coatings requiring high bonding force and low porosity; low-pressure plasma spraying can be used for metal or ceramic coatings requiring high bonding force and low porosity; explosive spraying can be used for important zero strengthening of components;

(4) Arc spraying should be used for metal spraying construction with a large amount of work;

(5) Plasma spraying should be used for some of the more expensive parts with higher coating performance requirements;

(6) For parts with particularly high safety requirements, tests and demonstrations must be carried out before selecting the spraying process and materials.

Hot information