There are many thermal spraying process methods, but each method has its own advantages and limitations. Different results will be obtained when the thermal spraying process is selected from different angles. Taking high-speed flame spraying as an example, when the metal is sprayed by the HVOF process. For alloys and cermet materials, high-quality coatings with high bonding strength (70MPa), high density (porosity < 1%), and low oxide content can be obtained, but this process has high operating costs and is not required for basic materials. Several disadvantages such as high heat and inability to spray oxide ceramics. Therefore, when choosing a thermal spraying process, specific analysis should be carried out for specific needs. The following analysis will be analyzed from four aspects: coating performance, spraying material type, spraying economic performance and on-site construction adaptability.

1. Selection principle based on coating performance

1) The spraying performance requirements are not high, the use environment has no special requirements, and the melting point of the spraying material is lower than 2500 ° C, the oxygen-acetylene flame spraying process with simple equipment and low cost can be selected. Such as general workpiece size repair and conventional surface protection.

2) The spraying performance requirements are high. For precious or critical components with harsh working conditions, plasma spraying can be used. Compared with oxyacetylene flame spraying, plasma spraying has high flame temperature, sufficient melting, non-oxidizing properties, high coating bonding strength and low porosity.

3) When the coating requires high bonding strength and extremely low porosity, high-speed flame (HVOF) spraying can be used for metal or cermet coatings; high-speed plasma spraying (such as Plaz) can be used for oxide ceramic coatings. Jet plasma spray). If spraying easily oxidized metal or cermet, controlled atmosphere or low pressure plasma spraying process must be used, such as Ti, B4C and other coatings.

2. The selection principle based on the type of spraying material

1) For spraying metal or alloy materials, the arc spraying process can be preferred.

2) When spraying ceramic materials, especially oxide ceramic materials or carbide and oxynitride ceramic materials whose melting point exceeds 3000°C, the plasma spraying process should be selected.

3) Spray oxide coatings, especially WC-Co, Cr3C2-NiCr nitride coatings, can choose high-speed flame spraying process, and the coating can obtain good comprehensive performance.

4) When spraying the biological coating, the controlled atmosphere or low pressure plasma spraying process should be used.

3. The principle of selection based on the economic behavior of coatings

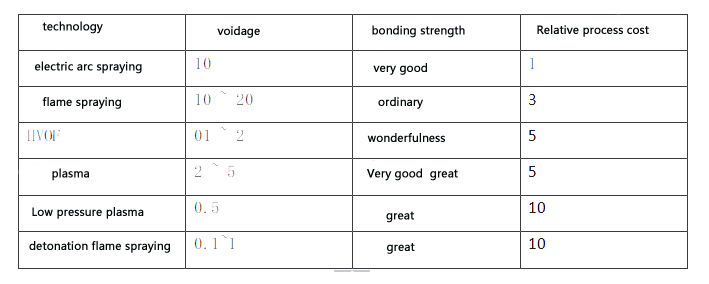

Under the condition that the cost of spraying raw materials is not very different, among all thermal spraying processes, arc spraying has the lowest relative process cost, and this process has the characteristics of high spraying efficiency, high bonding strength between coating and substrate, and suitable for on-site construction. The arc spraying process should be used wherever possible. The coating characteristics and relative costs of several major thermal spray processes are shown in the table.

Performance and cost comparison of several thermal spraying processes

4. Selection principle based on on-site construction as the starting point

When making process selection with on-site construction as the starting point, arc spraying should be the first choice, followed by flame spraying. Portable HVOF and low-power plasma spraying equipment can also be sprayed on site. At present, some people install the plasma spraying equipment on the mobile motor vehicle to form a mobile spraying workshop, so as to complete the long-distance on-site spraying operation.

Hot information