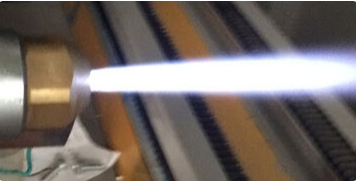

The composite process of thermal spraying and shot peening was used to prepare the coating on the surface of the main friction parts of the engine, and the SEM and metallographic observation, energy spectrum analysis, hardness test, sliding friction coefficient test and engine bench test verification were used in test experiments. The morphology, structure, composition and properties of the coating were studied, and the following conclusions were drawn.

1) The new technology of thermal spraying can change the surface morphology of the parts, and the micro scratches on the surface of the parts become pit-like, which enhances the oil storage effect on the surface of the parts. The spray coating contains MoS2 and other lubricating substances, but the coating cannot form a continuous film-like structure on the surface of the parts, and the adhesion of the coating substances is poor, and the falling particles are easy to enter the lubrication system, causing abnormal wear of engine parts and shortening the parts. service life.

2) After being treated by the new thermal spraying technology, the size and surface roughness of the parts do not change much, which meets the requirements of engine installation.

3) After the thermal spraying new technology, the sliding friction coefficient on the surface of the part increases slightly, from 0.142 to 0.152, but the difference in the friction coefficient becomes smaller and the friction coefficient stability improves.

4) It has been verified by the engine bench test that after the thermal spraying new technology is processed, the economy (fuel consumption rate) of the engine becomes worse, and the dynamic performance (power, torque) is reduced.

5) The new thermal spraying process has little effect on the matrix hardness and microstructure of the parts.

6) According to the process principle of the new thermal spraying technology and its effect on the improvement of the surface state of the parts, it can be speculated that by adjusting and optimizing the process parameters of the new technology, the composite process can give full play to the advantages of thermal spraying and shot peening performance at the same time, and achieve "1. +1>2" effect, then the new thermal spraying technology in this paper will be an excellent surface treatment process

Hot information