1. Enhanced surface hardness, increased service life and reduced maintenance costs

Application example: The screw conveyor of the concrete mixer is subjected to continuous, strong and severe wear caused by the conveying of concrete during operation. The wear-resistant coating made by thermal spraying technology greatly improves the wear resistance of the working surface of the machine and prolongs the service life.

2. restore size

2. restore size

Application example: The toner roller of the copier is worn down after long-term repeated use, resulting in blackening of the copying effect or black lines. The usual repair method is to replace the entire drum, and the original parts are discarded. The thermal spraying process can be used to spray a layer of alloy on the original drum, which not only restores the diameter of the original drum, but also makes the repaired drum more wear-resistant and has a longer service life, and the maintenance cost is only equivalent to one-fifth of the replacement parts. .

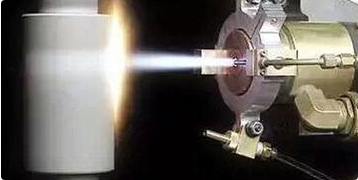

3. High temperature oxidation resistance

Application example: The jet engine combustion chamber needs to be sprayed with a special coating to resist high temperature oxidation during operation. After the chimneys of factories and ships are sprayed with high-temperature oxidation-proof coatings, the service life is increased by five times. Automotive sealing valves; blades of steam turbines.

4. Thermal Barrier Coating

Application examples: Generally used in diesel engine pistons, gas turbine combustion chambers, valves and flame stabilizers. After thermal spraying treatment, it can withstand the high temperature and high pressure in the working environment, and reduce the working temperature of the substrate to 10℃-65℃.

5. Cavitation resistant coating

Application examples: Plunger pumps on drilling platforms; steel furnaces; sprayed metal coatings for corrosion protection of structural steel are now commonly used in buildings, bridges, towers, radio, radio and television, structural steel, radar Antennas, overpasses, railway high-priced line pillars, power line towers, etc.

Application example: In order to deal with the erosion of the salt atmosphere, the wellhead devices on the sea surface have been sprayed since the 1950s. This technology has been used for external protection of conical cooling towers, oil and propane gas storage tanks.

6. Chemical resistance

Application example: The use of thermal spraying on the interior of liquid trucks can ensure the purity of liquid goods and prevent the pollution of iron magazines. Spraying zinc on railway vehicles can effectively prevent corrosion, and it is not necessary to carry out painting operations during operation. Thermal spray coatings can also be used to protect fresh water pipes, the interior of water towers and gates in hydraulic systems. These facilities can be used for ten years after spraying without maintenance. Thermal spraying is also widely used in offshore engineering. Thermal spraying has achieved good long-term protection for hulls, decks, concrete parts of barges, large flats, tugboats, etc.

Hot information