current position:Information and data>Tungsten carbide spraying process

The popularity of tungsten carbide spraying is becoming more and more widespread, and there are more and more places of application. For tungsten carbide spraying equipment, it is more and more important to strengthen and improve the service life, ensure the normal operation of the equipment, and reduce the energy consumption of enterprises. However, this technology has high requirements on the operation of the staff, and is usually completed by experienced technicians to ensure the spraying effect. Spraying construction should follow the following process:

Surface cleaning: use steel ball mechanical means to operate, and add alkaline cleaning solution to clean the surface, you can

Mainly use steel balls and other mechanical means, supplemented by alkaline cleaning fluid, to remove surface buoyancy layers such as rust and oil stains on the surface of the pipeline, and the cleanliness reaches SA3 level to ensure a firm bonding foundation. coating.

Surface roughening: Sandblasting and electric drawing are usually used to improve the mechanical bond strength between the coating and the substrate. The standard roughness is 6.5-25.

Spray bottom layer: The expansion coefficient of the bottom layer is very close to the base material, which mainly improves the bonding strength and thermal shock resistance of the working layer.

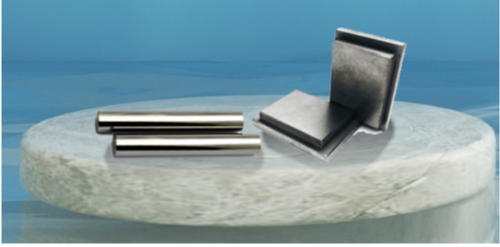

Spraying working layer: The spraying layer formed by tungsten carbide spraying equipment has good high temperature corrosion resistance and wear resistance.

Sealing treatment: After the coating is formed, there are certain voids, especially penetrating voids (<1%). Using a special high-temperature wear-resistant and anti-corrosion sealing coating, and spraying the gaps of the working layer, the performance of the sprayed layer can be optimized.

In practice, tungsten carbide spraying must follow this process to complete, so that tungsten carbide spraying can achieve good results. At present, many power plants, cement plants and other enterprises in our country have widely used this technology and played an important role in the production of enterprises.

Hot information