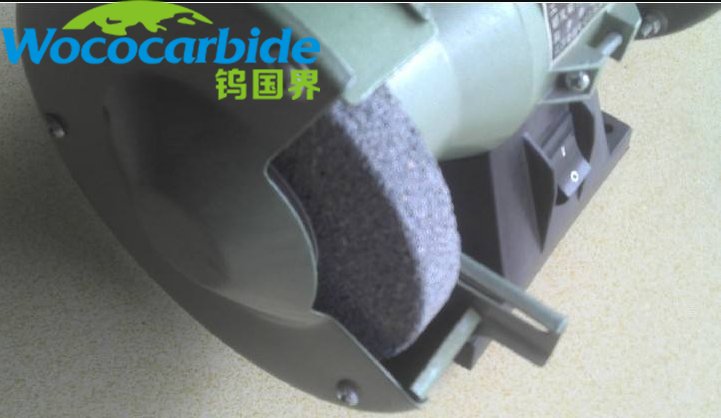

(1) The thickness of the grinding wheel should be selected according to the material and processing schedule requirements of the device to be processed. Softer metal materials, such as copper and aluminum, should use a coarser grinding wheel, and devices that require higher machining accuracy should use a finer grinding wheel.

(2) According to the shape to be processed, select the suitable grinding wheel surface.

(3) The grinding wheel used must not have defects or disabilities such as cracks, defects, etc., and the installation must be stable. This point should also be paid attention to in the process of use. Once the grinding wheel is found to have defects or disabilities such as cracks, defects, etc., stop using it immediately and replace it with new products; when it is active, it should be stopped immediately and tightened. (4) When grinding, the operator should wear protective glasses and gloves to prevent the splashing metal chips and sand from harming the human body.

5. The pressure applied to the grinding device should be appropriate. If it is too large, it will cause overheating and anneal the machined surface. In severe cases, it will not be used, and the life of the grinding wheel will be shortened too quickly.

(6) For devices with a width smaller than the grinding surface of the grinding wheel, during the grinding process, do not always grind one part of the grinding wheel, and should translate left and right on the grinding surface of the grinding wheel at a certain period, the purpose is to make the grinding wheel grind The cut surface can be kept relatively flat, which is convenient for subsequent processing.

(7) In order to prevent overheating annealing of the machined surface of the device being ground, the grinding part can be immersed in water for cooling at any time.

(8) Regularly measure the insulation resistance of the motor, which should preferably be no less than 5MΩ. A circuit breaker with leakage protection device should be used to connect to the power supply.

Hot information