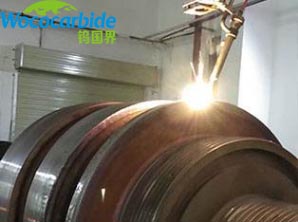

Spraying refers to a series of processes in which fine and dispersed metallic or non-metallic coating materials are deposited on the surface of a prepared substrate in a molten or semi-molten state to form a certain spray deposition layer. It uses a certain heat source (such as arc, plasma spraying or combustion flame, etc.) to heat powder or filamentary metal or non-metallic materials to a molten or semi-molten state, and then sprays them at a certain speed with the help of the flame itself or compressed air. A technique in which a pretreated substrate surface is deposited to form a surface coating with various functions. A new preparation method of ultrafine copper-zinc powder was proposed by combining thermal spraying method with mechanical ball milling method.

On the basis of powder preparation using conventional thermal spraying process parameters, the effects of ball milling time, ball milling aids and heat treatment conditions on powder properties were discussed, and the best preparation scheme was obtained. The method can prepare ultra-fine copper-zinc powder with uniform particle size distribution, stable properties and particle size of 200-500 nm. Aiming at the fact that ultrafine copper-zinc powder has serious agglomeration in liquid medium, the dispersion effect of the powder under the action of different dispersants was studied by sedimentation method and spectrophotometry. The formulation of the dispersant was optimized by the orthogonal test method, various factors affecting the dispersing performance were analyzed, the action mechanism of various dispersants was discussed, and the optimal action conditions of different dispersants were found. It provides an effective way to obtain ultrafine powder with stable properties.

The results show that the ball milling process and heat treatment parameters have important effects on the properties of copper-zinc powder. In the initial stage, with the increase of the ball milling time, the powder particle size becomes larger, and the powder particle size becomes smaller when the ball milling is continued. The addition of ball milling aids improves the ball milling efficiency, improves the ball milling effect, and significantly improves the dispersibility of the powder. After heat treatment, the particle size of the powder increases, the proportion of fine particles decreases, and cracks appear on the surface, which reduces the hardness of the powder and weakens the agglomeration of the powder.

Hot information