Surface engineering is one of the key technologies of industrial development in the 21st century. Surface technology is divided into three categories: surface modification technology, thin film technology and coating technology. Thermal spraying technology is a very important technology in the field of surface engineering, accounting for about 1/3 of the technology is a new technology for the repair and pre-protection of mechanical parts developed abroad in the 1950s. It can prolong the service life of parts and components of various mechanical equipment vehicles.

The coating can strengthen or regenerate the surface properties of the material (wear resistance, corrosion resistance, heat resistance, etc.), play a protective role, and repair the size reduction of parts caused by wear and corrosion or excessive processing. At the same time, it can also impart special properties (electricity, light, magnetism, etc.) to the surface of the material. At present, the widely used methods in production are mainly flame spraying (including wire flame spraying, powder flame spraying, supersonic flame spraying, explosive spraying, etc.), plasma arc spraying and electric arc spraying. Based on the huge potential of the thermal spraying market and its social and economic benefits, thermal spraying technology has received great attention worldwide.

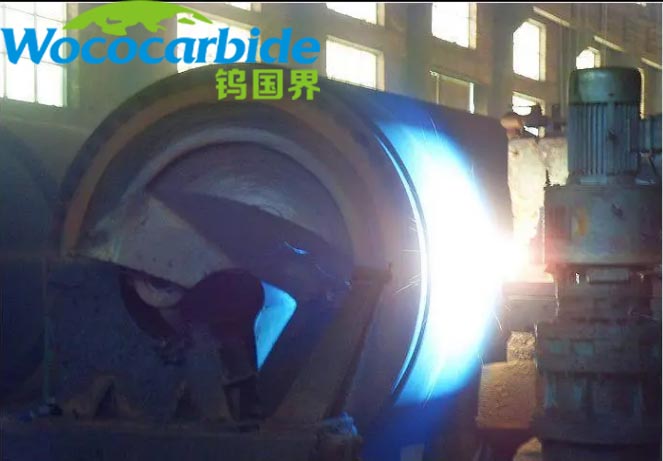

Hot information