Thermal spraying manufacturers briefly introduce spraying requirements

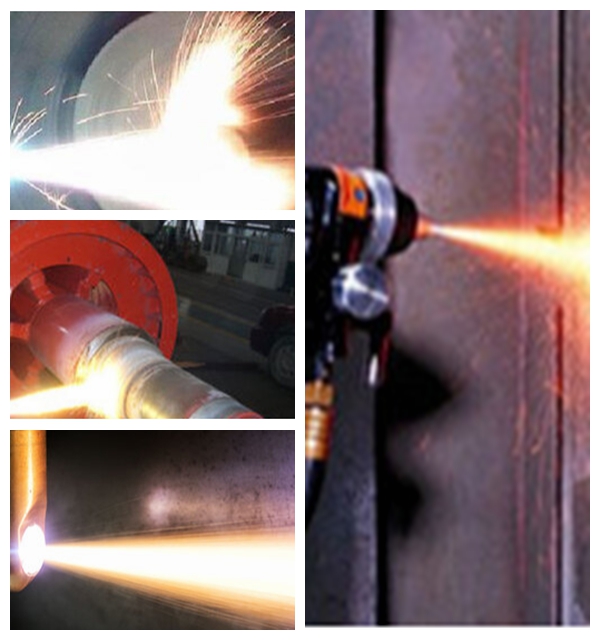

The main equipment for thermal spray zinc includes compressed air system, oxygen, acetylene system, metal air spray gun, hose, etc. Its working principle: the compressed air in the spray gun is the driving force. Driven by the driving device, the zinc wire becomes molten through the nozzle under the heating of oxyacetylene flame, atomized into particles by compressed air, and sprayed into the workpiece to form a thermal spray zinc protective layer. Due to the uneven surface of the substrate after sandblasting, the metal coating after heat dissipation and shrinkage can be firmly attached to the surface of the workpiece.

Spraying requirements:

1. The purity of zinc wire for metal spraying is not less than 99.99%.

2. The zinc wire should be smooth, rust-free, oil-free, and crease-free, with a diameter of 2.0~3.0mm.

Spraying process requirements:

The compressed air for spraying should be clean and dry, and the pressure should not be lower than 0.4MPa.

2. The spray distance is 100~200mm, and the spray gun should be at right angles to the surface of the substrate as much as possible, not less than 45°.

3. The moving speed of the spray gun, the thickness of one spray is 25~80μm.

4. There should be one-third of the width overlap between the spray strips, and the thickness should be as uniform as possible.

5. The directions of the spray guns between the spraying layers should be perpendicular to each other for cross coverage.

6. When the surface temperature of the coating drops below 70℃, the next layer of spraying will be carried out.

Hot information