The coating material can be in the form of powder, ribbon, wire or rod. Thermal spray guns provide the necessary heat from a gas, electric arc or plasma arc to heat the thermal spray material to a plastic or molten state, which is then accelerated by compressed air to impinge a confined beam of particles on the surface of the substrate. Particles impacting the surface are deformed by the stamping to form a laminate that adheres to the surface of the substrate, which then cools and accumulates to form a layered coating. Due to the different coating materials, the coating has functions such as high temperature corrosion resistance, wear resistance, heat insulation, and electromagnetic waves.

Classification of thermal spray should be done in the form of a heat source. On this basis, if necessary, spray material (powder, wire, rod), material properties (metal, non-metal), energy level (high energy, high speed), spray environment (atmosphere, vacuum, negative pressure), etc.

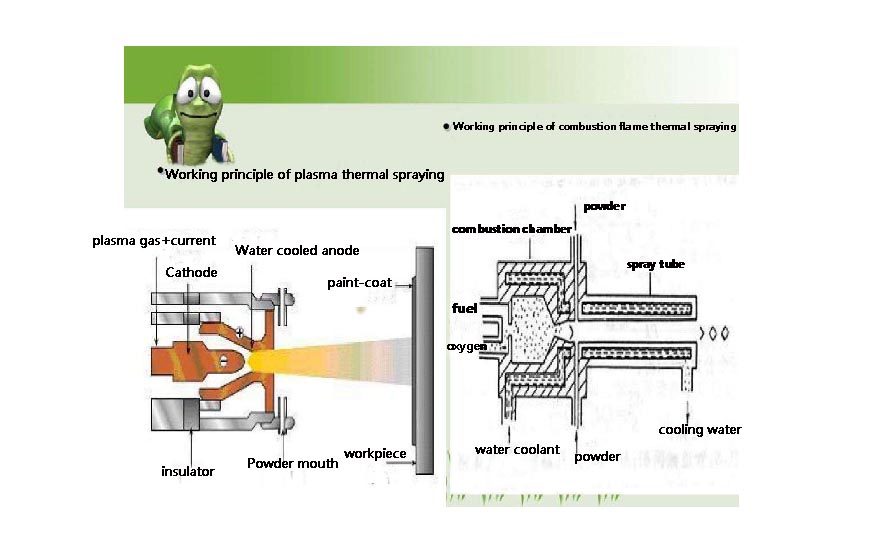

Thermal spraying can be divided into four categories: flame spraying, arc spraying, plasma spraying and special spraying.

Thermal spray equipment and technology.

Although the equipment varies depending on the thermal spraying method, according to the principle of thermal spraying technology, the equipment mainly consists of a spray gun, a heat source, a paint supply device, a control system and a cooling system.

The thermal spraying process is: workpiece surface pretreatment→workpiece preheating→spraying→coating post-treatment.

1) Surface pretreatment.

In order to make the coating bond well with the substrate, the surface of the substrate must be clean and rough, and there are many methods for surface cleaning and roughening. The choice of method should be based on factors such as coating and substrate design requirements, shape, thickness, original surface conditions, and construction conditions. The purpose of purification treatment is to remove all dirt on the surface of the workpiece, such as scale, oil stains, paint, etc. The key is to remove the surface of the workpiece and penetrate the oil.

2) Preheat

The purpose of preheating is to eliminate moisture and moisture on the surface of the workpiece, increase the interface temperature between the sprayed particles and the workpiece, thereby improving the bonding strength of the coating and the substrate, and reducing the stress and coating material caused by the thermal expansion difference of the substrate.

3) Spray

The spraying method mainly depends on the spraying material, the working conditions of the workpiece and the quality of the coating.

4) Post-coating treatment.

The resulting coatings are sometimes not usable directly and must undergo a series of post-treatments.

Hot information