The reproduction project adopts advanced repair technology, strict product quality control and accurate cost accounting, so that the old products can be reproduced to achieve good technical and economic indicators. sustainable development strategy. The resumption of work and production projects is based on advanced maintenance processes, of which thermal spraying technology is widely used in resumption of work and production due to its process flexibility, controllability of coating quality and cost advantages. According to the principle of thermal spraying, the state of particles before deposition determines the properties of the coating, including particle velocity, particle temperature and particle melting state.

1 Supersonic arc spraying technology.

Arc-shaped coating has the advantages of high production efficiency, low production cost and low heat of workpiece. It is widely used in long-term anti-corrosion and wear-resistant coating. It occupies an important position in thermal coating, but it is different from plasma coating and supersonic flame coating. Compared with ordinary arc coating, the coating quality is low, the bonding strength is about 20MPa, and the porosity is 3%-10%. The supersonic arc spraying takes the increase of particle speed as the starting point, and the Laval nozzle is used to improve the atomization of the spray gun. The effect is enhanced, the acceleration effect of airflow on particles is enhanced, the particle velocity is increased to supersonic speed, the prepared coating has high bonding strength, low porosity, low surface roughness, and the coating quality is greatly improved compared with ordinary arc spraying.

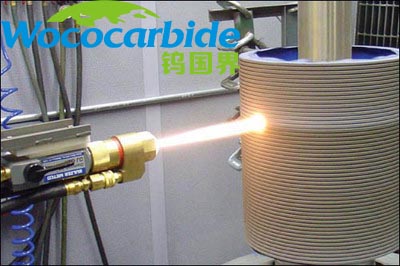

The principle of supersonic arc coating is that the arc burning at the end of the wire melts the wire that is evenly fed, and the molten wire is atomized into particles with fine particle size and uniform distribution by the supersonic airflow accelerated by the Laval nozzle, which is sprayed onto the workpiece to form coating. Like ordinary arc spraying, supersonic arc spraying is a continuously repeated melting-atomization-deposition process, but in the way of atomization, supersonic arc spraying is different from ordinary arc spraying. Sonic arc spraying adopts supersonic spraying. After atomization, the particles are fine and uniform, and the speed is high, which is conducive to obtaining high-quality spraying.

2 The application of supersonic arc coating in reproduction.

The supersonic arc spray coating has high bonding strength, low porosity, low surface roughness and good wear resistance, and has broad application prospects in industry, especially in long-term anti-corrosion and wear-resistant coatings. The supersonic arc coating technology is flexible, and the coating with excellent performance can be obtained within a considerable technical parameter range. After the successful development of the equipment, it has been widely used

Hot information