With the application of high technology, the level of industrial production technology has been continuously improved. The working mode of high speed, highest efficiency and high quality has become the goal that people are increasingly pursuing, which puts forward higher requirements for the comprehensive performance of mechanical parts. Improving the comprehensive application of materials and improving the surface properties of materials has long been a problem that scientists and technicians care about. Thermal spray technology is a widely used surface modification technology in the field of surface engineering.

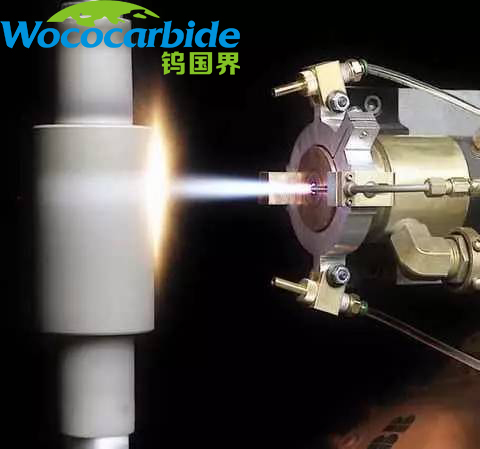

Thermal spraying refers to a series of processes in which finely dispersed metallic or non-metallic coating materials are deposited in a molten or semi-molten state on the surface of a prepared substrate to form a spray-deposited layer. It is a technology that uses a certain heat source (such as arc, plasma spray or combustion flame, etc.). ) Heating powder or filamentary metal or non-metallic material to a molten or semi-molten state, then spraying it into the pretreated substrate surface with flame holding or compressed air at a certain speed, and depositing it to form a surface with multiple functions coating. Utilize energy provided by gas, arc, etc.

The application of high and new technology has continuously improved the technical level of industrial production. The working mode of high speed, highest efficiency and high quality has become the goal that people are increasingly pursuing, which puts forward higher requirements for the comprehensive performance of mechanical parts. Improving the comprehensive application of materials and improving the surface properties of materials has become a problem that people are very concerned about. Thermal spraying technology is one of the effective surface modification technologies in the field of surface engineering.

According to the definition of the national standard GB/T18719-2002 "Terms and Classification of Thermal Spraying", thermal spraying technology is to use a heat source to heat the sprayed material to melt or semi-melt, and to form a coating on the surface of the pretreated substrate at a certain speed. Methods for special features of substrate surfaces.

The main surface coating application process.

Coating process, coating thickness, commonly used coating materials and typical applications. There are many factors to consider, such as some processes may not be suitable for certain materials, or some processes cannot obtain the required coating thickness, or some processes require very complex equipment, so the cost is high. The cost analysis generally determines the actual application scheme of the coating, and at the same time considers environmental factors to achieve ecological standards.

Hot information