current position:Information and data>The principle of supersonic arc spraying

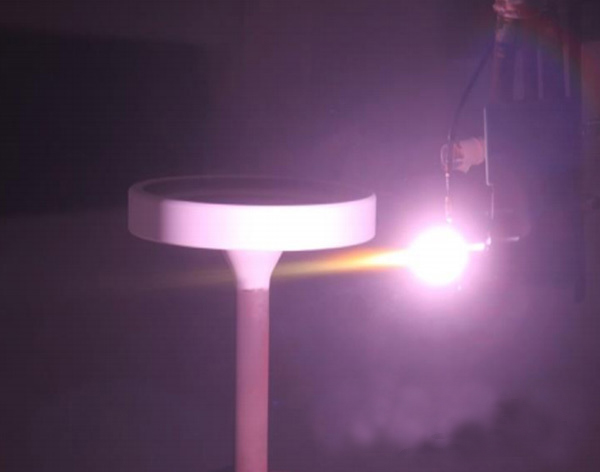

The principle of arc spraying is to use two continuously fed metal wires as consumable electrodes, generate an arc at the end as a heat source, atomize the melted wire with compressed air, and spray it to the workpiece at supersonic speed to form a A thermal spray method for coatings with high bond strength, low porosity and low surface roughness.

The principle of arc spraying is to use two continuously fed metal wires as consumable electrodes, generate an arc at the end as a heat source, atomize the melted wire with compressed air, and spray it to the workpiece at supersonic speed to form a A thermal spray method for coatings with high bond strength, low porosity and low surface roughness. Its working principle is the same as that of ordinary arc spraying (subsonic atomization). Supersonic arc spraying is a continuous melting-atomizing-deposition process. However, in terms of atomization, there is a fundamental difference between supersonic arc spraying and ordinary arc spraying, that is, supersonic arc spraying uses supersonic atomization. Its advantages are: good atomization effect, fine and uniform particles after atomization, and high speed, which is conducive to obtaining high-quality coatings. Supersonic arc spraying uses a Laval nozzle to increase the speed of the air flow from subsonic to supersonic, strengthening the air flow to the particles, thereby increasing the particle velocity. Particle velocity has a large effect on the performance of the coating. The higher the particle velocity, the stronger the impact on the substrate when the particles are deposited, and the sufficient particle deformation. It is beneficial to the bonding between particles and substrates, particles and particles, thereby improving the bonding strength and cohesive strength of the coating; the particle velocity is high, the flight time of the particles in the air before deposition is short, and the oxides produced in the flight are less, It is beneficial to the bonding of particles, thereby improving the cohesive strength of the coating and reducing the porosity of the coating. The higher the particle velocity, the more favorable it is to obtain a high-quality coating. With the upgrading of thermal spray equipment, particle velocities continue to increase, and the quality of coatings continues to improve.

Supersonic atomization reduces particle size and reduces coating roughness. Roughness is an important performance index of the coating, which depends on the particle size of the atomized particles. Supersonic atomization strengthens the effect of airflow on the molten metal at the end of the wire, and the atomized particles are fine and uniform, which greatly reduces the roughness of the coating. At the same time, the reduction of particle size also reduces the splash during the particle flattening process, which is beneficial to reduce the porosity of the coating.

Supersonic atomization is the starting point of supersonic arc spraying, and it is the fundamental difference between it and ordinary arc spraying.

Supersonic arc spraying equipment includes power supply, spray gun, wire feeding mechanism and its accessories. The key equipment is supersonic arc spray gun. Our company adopts imported nozzles, and the spraying current is stable. On the premise of ensuring the atomization effect of the wire and the quality of the coating, the spraying area can reach 20 square meters.

During arc spraying, the temperature of the arc zone is as high as 5000-6000℃, and the nozzle is cooled by air cooling.

Hot information