Our company produces tungsten-containing compound carbides using tungsten powder instead of traditional tungsten carbide. We believe that the use of tungsten powder can not only reduce costs, but also improve product quality.

1. It can make the crystal lattice of the compound carbide more complete and the solid solubility higher.

The current production process of ordinary CK material is: WC+TiO2+C is sintered at high temperature. Because the dissolution process of WC into TiC is not the whole inward dissolution, but the decomposition of WC into W and C, respectively. Because their solid solutions are divided into two forms, W dissolves in TiC as a substitutional solid solution, while C dissolves in TiC as an interstitial solid solution. At this point, a problem arises because during the batching and mixing process, WC, TiO2, and C are mechanically mixed, so carbon black forms a uniform distribution around WC and TiO2. We know that a large amount of carbon black is required to deoxidize and carbonize TiO2, and WC itself does not require carbon black. Therefore, in a limited time and temperature, the diffusion of carbon black alone to deoxidize, carbonize and make WC solid solution cannot achieve the best effect. In particular, when Ta and Nb are also contained, the effect is even worse.

But if you switch to W powder, the situation is very different. Because the W powder itself also needs carbon black for carbonization, there is an appropriate amount of carbon black around it and will not form excess. In this way, the diffusion strength of carbon black is reduced. In addition, since the affinity of Ti and C is greater than that of W and C, TiO2 is more easily reduced and carbonized, so that the entire solid solution structure is more complete and carbonized more fully.

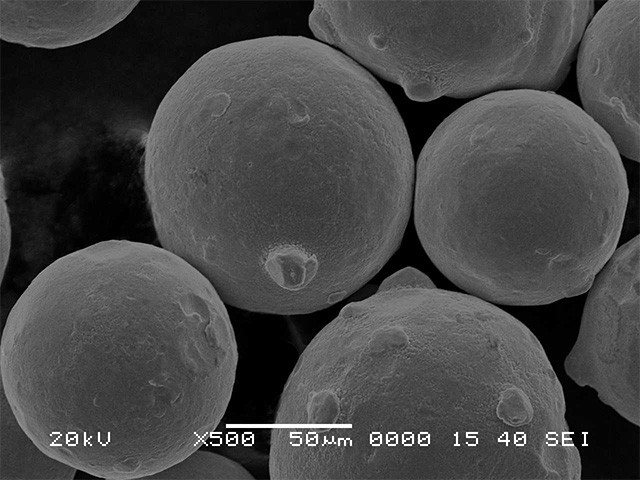

Second, the particle size is more uniform and finer.

In my opinion, using W powder will make the mix more balanced to receive energy than using WC as the raw material. Because, WC itself is a compound formed by W+C under the action of high temperature. In the process of increasing the temperature, a considerable part of WC will continue to aggregate and thicken before the solid solution, so the particle size of the solid solution will be uneven. However, if W powder is used, as the temperature increases, part of the W powder is directly dissolved in TiC, and the other part is combined with C to form WC under the condition of increasing energy. This eases the process of particle coarsening, resulting in a more uniform particle size for the solid solution. It is well understood that the use of W powder can reduce the particle size of the solid solution. Because under the same sintering temperature and time, the carbonization of W powder itself requires energy.

3. It can reduce the free carbon and oxygen of solid solution.

Because the use of W powder as a raw material can make carbon black react with TiO2, Ti, and W more fully and effectively, it is a matter of course that the free carbon and oxygen of the solid solution are reduced.

Fourth, have better bulk density.

After using W powder, the carbon black of the ingredients increases and the volume of the raw materials increases, thus reducing the loading amount of each boat, so the formed product is looser, easier to break, and has a better bulk density.

Hot information