current position:Information and data>Design of Plasma Inner Hole Spraying Device

To prepare the coating on the inner surface or the inner cavity surface, a special inner hole plasma spray gun should be used. The inner hole parts are best placed vertically, the purpose is to facilitate dust removal. The inner bore plasma spray gun is usually mounted on an adjustable cross arm when spraying. The spray gun moves up and down along the inner wall of the hole parts, and the movement stroke is controlled by the stroke switch. Reasonable selection of the speed of the up and down movement of the spray gun and the rotation speed of the workpiece is an important prerequisite for obtaining a satisfactory inner hole spray coating. The rotational speed of the workpiece is directly related to the diameter of the inner hole of the workpiece, the size of the workpiece and the wall thickness.

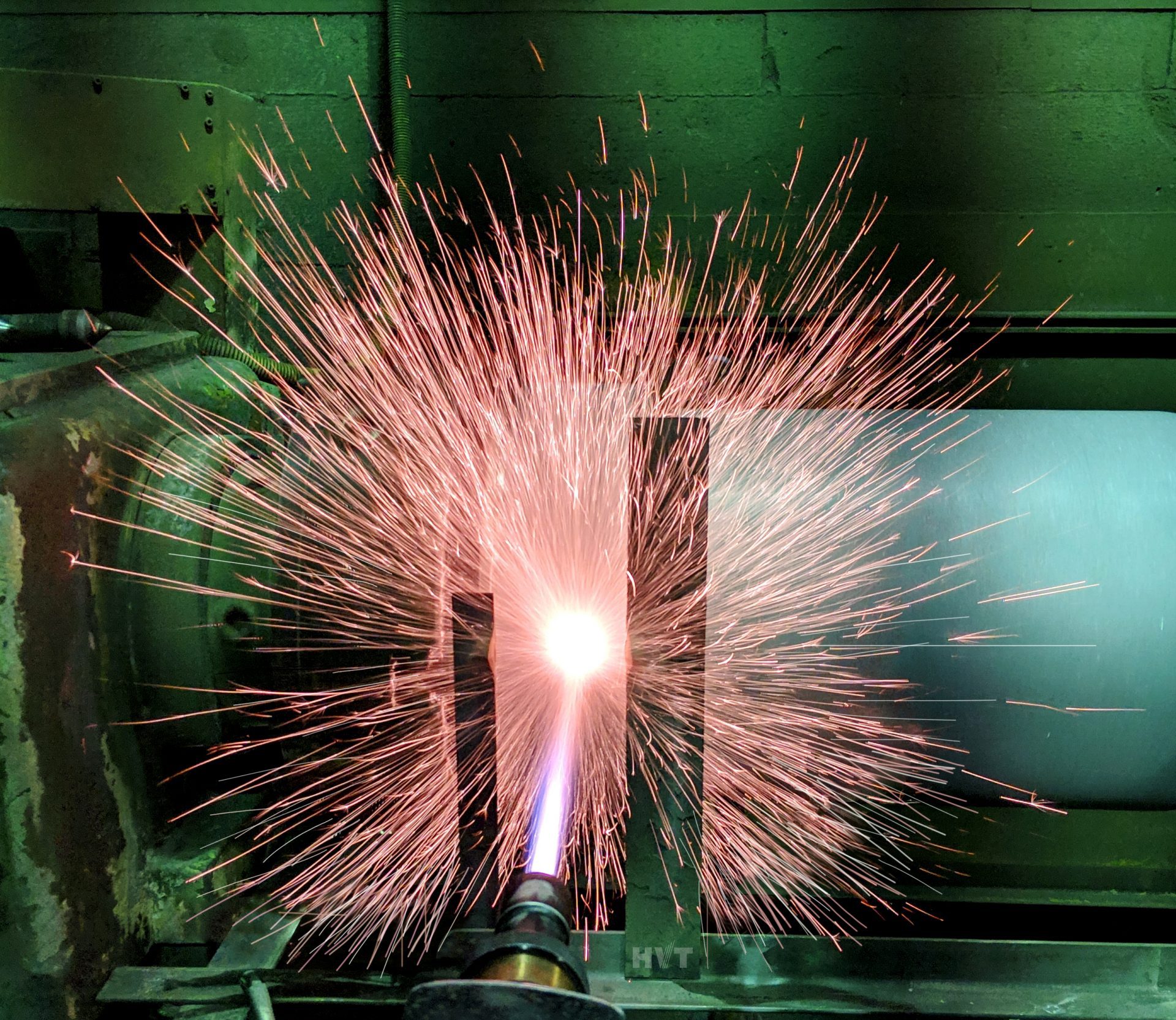

In addition, the inner hole spraying can also be realized by the method of keeping the workpiece stationary, the plasma spray gun rotating at a certain speed, and moving vertically along the central axis of the inner hole. This method requires a special device to rotate the plasma spray gun, while ensuring the stability of the working gas, powder feeding and cooling water in the spray gun.

When spraying blind holes, special attention should be paid to heat dissipation and dust removal. It is the most difficult to spray small blind holes, and the dust generated during spraying will accumulate in the coating, which will seriously affect the quality of the coating. Therefore, it is necessary to extend the auxiliary ventilation pipe into the blind hole to supply fresh air from the bottom of the hole, so that the sprayed surface can be properly ventilated. In addition, the substrate should be sufficiently preheated to pre-expand the substrate structure, so that the adhesion between the coating and the substrate will not generate too much stress after spraying.

Hot information