In actual use, due to the huge differences in the shape, size, material, use environment and service conditions of the parts, in order to obtain the best performance of the coating, all the links involved in the thermal spraying technology must be integrated together for optimization. In particular, attention should be paid to combining the spraying materials with the characteristics of various thermal spraying processes, including the selected spraying materials, coating thickness, corresponding spraying equipment and process parameters, etc. Whether the coating structure design is reasonable generally needs to pass the production inspection or field trials to determine. In thermal spray application technology, the coating structures involved can be roughly divided into the following four types:

1. Single-layer structure

Single-layer structural coating refers to a coating structure mode that only needs to spray a single-component coating on the surface of the pretreated parts to meet the performance requirements. It accounts for a large proportion in practical applications and is one of the most commonly used thermal spray coating structures, which can provide the substrate with functions such as corrosion resistance, wear resistance, high temperature oxidation resistance, electrical conductivity, size repair, and extended service life. All thermal spraying processes, including ordinary flame spraying, spray welding, arc spraying, HVOF, explosive spraying, plasma spraying, etc., can obtain single-layer structural coatings with specific properties.

2. Double layer structure

The double-layer structural coating refers to the coating structure formed by two spraying materials on the surface of the pretreated part in two times, and each layer has different functions. Usually the coating adjacent to the substrate is called the bonding bottom layer, and its main function is to improve the bonding strength between the substrate and the coating; the outer layer or surface layer is called the working layer or surface layer, and its main function is to meet the requirements of the part. performance. This structural coating also accounts for a large proportion of practical applications, and is also one of the most commonly used thermal spray coating structures. The two coatings can be completed by the same thermal spraying process, such as using a single process method, such as ordinary flame, explosive spraying or plasma spraying to spray the two coatings separately; it can also be completed by different thermal spraying methods, such as The bottom layer can be bonded by arc spraying, and then the surface working layer can be sprayed by plasma, or the bottom layer can be bonded by high-speed flame spraying first, and then the surface working layer can be bonded by plasma spraying. This combination is a typical process for the preparation of thermal barrier coatings for aircraft engines.

3. Multilayer structure

Multilayer structure refers to a coating structure with three or more coating layers, which is not commonly used in practical applications and is only used under special working conditions.

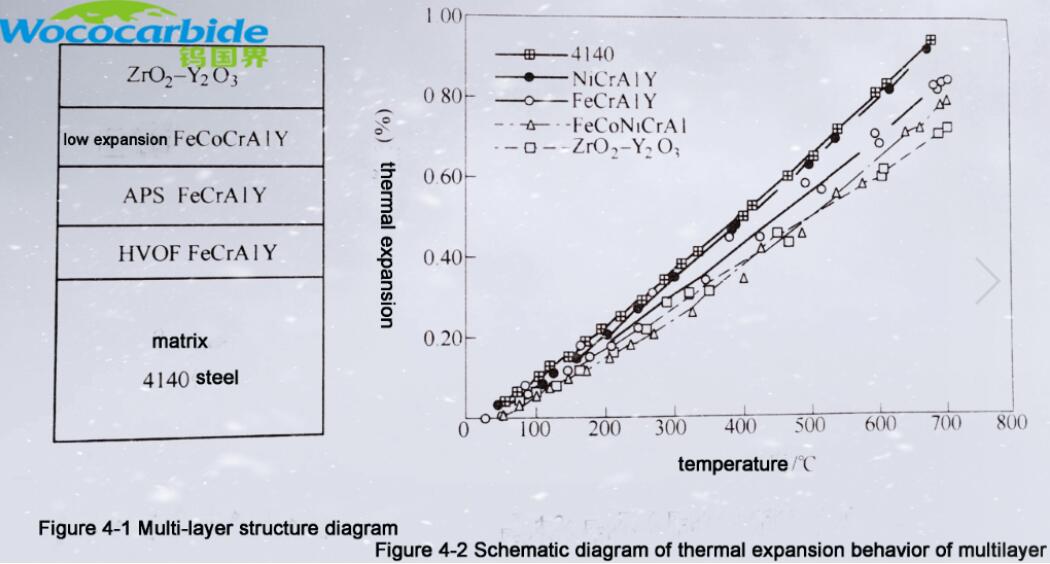

Some multi-layer structures meet one performance requirement by using multi-component coatings. For example, in order to develop a long-life thick thermal barrier coating that can meet the requirements of diesel engines, Robert et al. used a combination of three layers with very close thermal expansion coefficients. bottom layer to reduce thermal stress of the coating. Its multi-layer structure is shown in Figure 4-1, and the thermal expansion behavior of each layer is shown in Figure 4-2. Since the expansion coefficients between the matrix materials 4140, NiAIY, FeCrAIY FCoNiCrAl and ZrO2-Y2O3 are gradually changed, the thermal expansion mismatch between the ZrO2-Y2O3 coating and the matrix can be greatly reduced to reduce thermal stress, The purpose of prolonging the service life.

Hot information