The determination of powder density includes the determination of true density, bulk density and tap density of powder.

(1) True density There are many methods to measure the true density of powder, generally using the pycnometer method. Key points of the method: Weigh the mass of the empty pycnometer and the mass of the pycnometer when it is filled with liquid medium, and obtain the volume of the pycnometer. The volume of the pycnometer is calculated as follows:

V=(m2-m1)/ρf

in the formula

m1---weighing of empty pycnometer;

m2---weighing the pycnometer when it is filled with liquid medium;

ρf---density of liquid medium.

Put the weighed powder into a pycnometer and weigh (m3), then fill it with liquid medium and weigh (m4), the true density of the powder is calculated as follows:

ρf=(m3- m1)xρf/(m2+m3-m1-m4)

Distilled water is usually used as the liquid medium. In order to improve the wettability of water to the powder, a few drops of methanol or xylene can be added to the water.

(2) The bulk density is usually measured by a funnel-type Hall flowmeter. The loose density of powder means that the powder falls freely from the funnel hole at a certain height to fill the cup. In the loose state, it is expressed by the mass of the powder per unit volume. It is the bulk density measured after the powder is freely filled in a standard container under specified conditions, that is, the mass per unit volume of the powder when it is loosely packed, commonly used in g/mL, and is also used to describe the properties of the powder. The bulk density test can be performed at the same time as the flow test. After each measurement of the powder fluidity, use a steel ruler to scrape the powder in the measuring cylinder (25mL) under the funnel, weigh out the mass of the powder in the volume, and repeat three times, take the arithmetic mean, and the mass record is accurate to +0.1g . The bulk density of the powder is obtained by dividing the mass by the reduced volume.

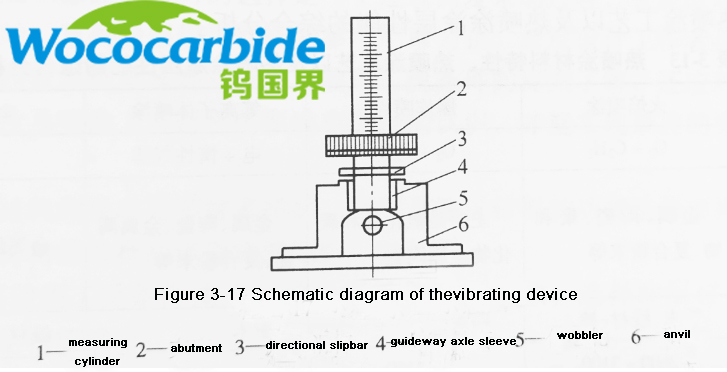

(3) Tapped density Tapped density refers to placing a quantitative powder in a vibrating container and vibrating under specified conditions until the volume of the powder no longer decreases, measure the tapped volume of the powder, and divide it by the mass of the powder. Density is obtained by the volume of the powder after taping, in g/cm.

Figure 3-17 is a schematic diagram of the tap density measuring device. The measuring device can automatically record the number of vibrations. Generally, it takes more than 3000 times of vibration to achieve the ideal vibrating effect. After vibrating about 3,000 times by the tap density tester, take out and read the powder volume. If the powder on the upper surface of the measuring cylinder is not on the same plane after the vibration is stopped, the arithmetic mean of the highest point and the lowest point should be taken when reading the data. Divide the weighed mass by the volume to obtain the tap density of the powder.

Hot information