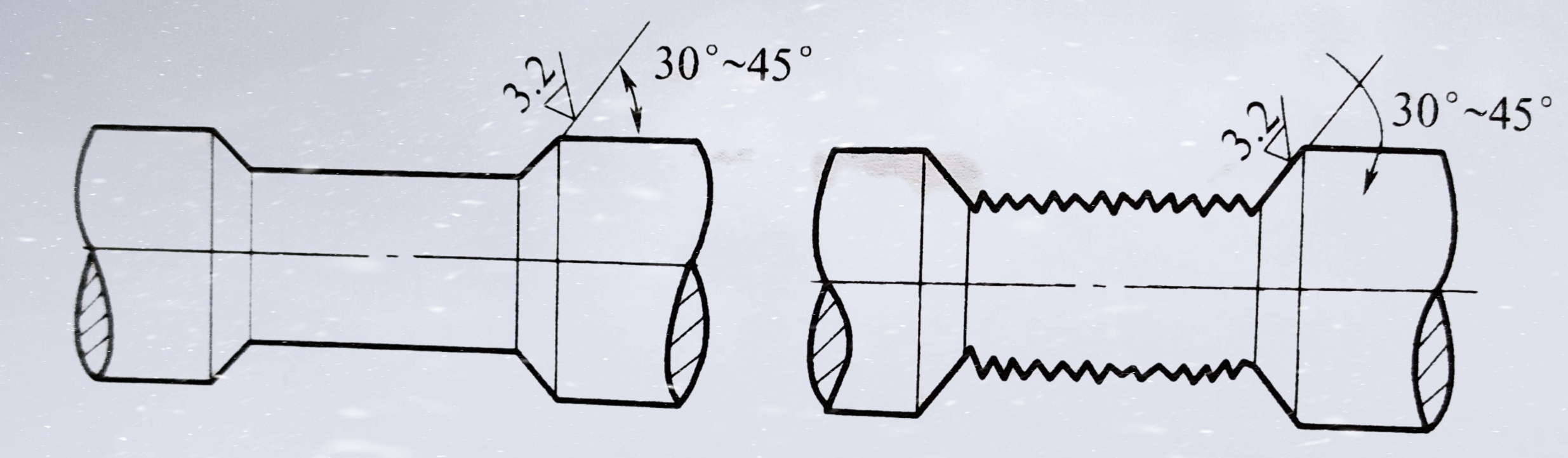

Rotary parts such as shafts, etc., can be roughened by turning the thread method, and the damage or fatigue layer can be removed at the same time, and the thickness of the spray layer can be reserved.

In general, a 90-degree V-shaped tool can be used, and the pitch is 0.5mm~0.6mm. The tip of the tool should be rounded to avoid sharp cutting. If deep grooves are not desired, the infeed depth should be 50% of the standard thread depth. For very thick coatings, using a thread with a pitch of 0.85mm to 1.0mm can produce a strong bond. The influence of thread shape and pitch is not too important on the spray effect. For very thick coatings with very strong bond strength, round bottom grooves can be used. The groove width is 1.1mm~1.3mm, the depth is about 0.6mm~0.8mm, and the chamfering radius of the blade used is about 0.13mm. The ridge tops between the grooves are wide, about 0.38mm for flexible materials and 0.64mm for brittle materials. When spraying on a surface with such grooves, the first few times, the spray gun should be at an angle of about 45 degrees to the sprayed surface Alternate sprays to ensure the coating fills the grooves.

Hot information