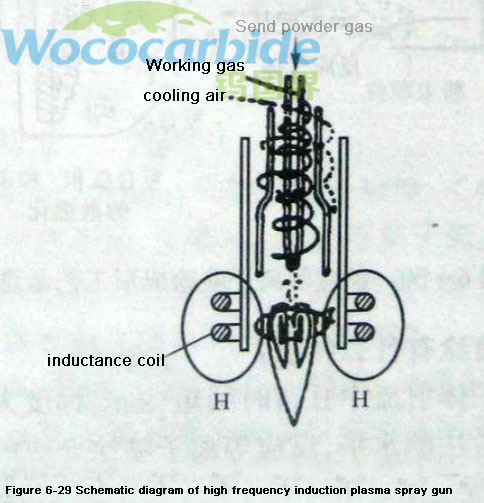

As shown in Figure 6-29, the spray gun is a three-layer quartz tube structure, and the powder gas is sent to the gun mouth from the central hole, where a carbon rod for pre-discharge is installed. The working gas (Ar, H2, etc.) is fed from the middle layer, the induction plasma arc is in the middle of the muzzle, and the cooling gas flows from the outermost layer

At present, Al2O3 and ZrO2 porous coatings have been prepared by RF plasma spraying, the porosity is 12% ~ 15%, the heat resistance is excellent, and the coating distortion is small and the toughness is good. The YBaCuO superconducting coating is prepared, and the resistance is 0 at 82K. , RF plasma flame has low heat load, and its sprayed particles impact the substrate at a low speed, which can reduce the damage to the prefabricated fibers of the substrate. Therefore, RF plasma spraying is a composite of preparing coarse-grained powder coating and spreading coating on continuous fibers. Ideal means of material.

Hot information