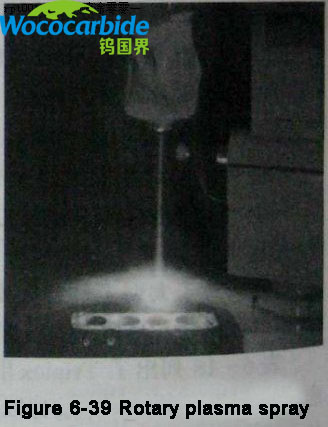

Rotary plasma spraying is particularly suitable for inner hole spraying. The workpiece remains stationary during spraying, and the plasma spray gun rotates at a certain speed and moves vertically along the central axis of the inner hole. The key technology of the system is a special device to make the plasma spray gun rotate (up to 200r/min), and to ensure the stability of the working gas, powder feeding and cooling water in the spray gun.

The rotary plasma spraying system (Rota Plasma500) developed by Sulzer-Metco has been used to spray the wear-resistant and heat-resistant coating on the inner wall of the Volkswagen Lupo FSI automobile engine cylinder. The system only needs 90s to spray a cylinder bore with a diameter of 80mm and a depth of 120mm, and the coating thickness is 150μm~200μm.

The rotary plasma spraying system (Rota Plasma500) developed by Sulzer-Metco has been used to spray the wear-resistant and heat-resistant coating on the inner wall of the Volkswagen Lupo FSI automobile engine cylinder. The system only needs 90s to spray a cylinder bore with a diameter of 80mm and a depth of 120mm, and the coating thickness is 150μm~200μm.

However, due to the characteristics of rotary plasma spraying itself, the spraying distance cannot be adjusted, and it can only be used for a special gun. When it is necessary to spray workpieces with different inner diameters, the gun must be changed.

Rotary plasma spray is shown here.

Hot information