current position:Information and data>The principle of gas-stabilized plasma spraying

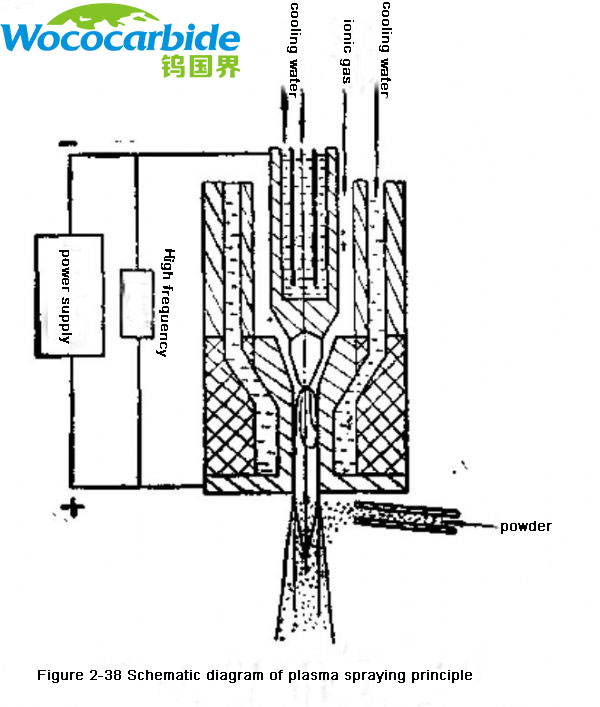

Gas-stabilized plasma spraying is plasma spraying that uses gas to generate plasma and stabilize the plasma arc. The spraying principle is shown in Figure 2-38. The plasma jet (arc flame) is generated by the plasma spray gun (plasma arc generator). The electrode (cathode) and nozzle (anode) of the spray gun are respectively connected to the positive and negative electrodes of the rectifier power supply, and are directed to the The lance is supplied with working gas (Ar, N2, etc.), which ignites the arc through a high-frequency spark. The arc heats the gas to a very high temperature to ionize the gas. Under the action of thermal shrinkage, self-magnetic shrinkage and mechanical compression, the arc is compressed to produce a non-transfer plasma arc. After the high-temperature plasma gas is ejected from the nozzle, the volume expands rapidly to form a high-temperature high-speed plasma jet. After the powder feeding airflow pushes the powder into the plasma jet, it is rapidly heated to a molten or semi-molten state, and is accelerated by the plasma jet to form a spray particle beam that flies to the substrate, which successively hits the surface of the pretreated substrate to form a coating .

Hot information