current position:Information and data>Spray guns for arc spraying equipment

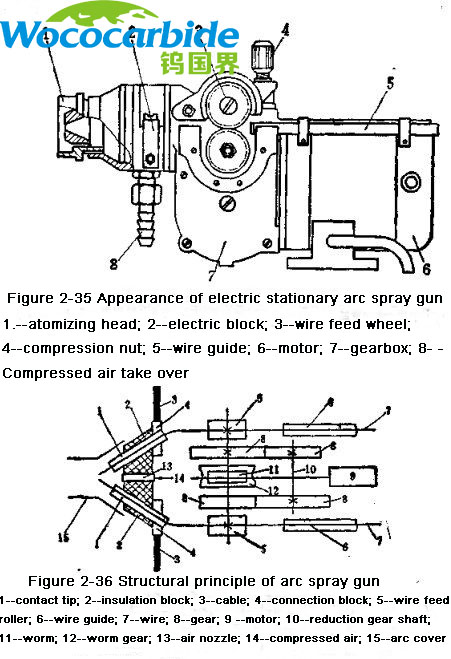

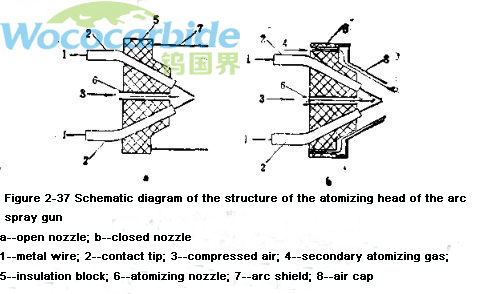

The arc spray gun is the main tool for arc spraying. The progress of the arc spraying technology is inseparable from the improvement and development of the spray gun. The appearance is shown in Figure 2-35, and the structure principle is shown in Figure 2-36. The two wires introduced into the spray gun meet at a certain angle through the wire guide tube and the contact nozzle, driven by the wire feed roller. Fasten the contact tab on the contact tip, and connect the power supply through the flexible cable. The wire is charged by contacting the contact tip. The introduced compressed air forms a high-speed airflow through the air nozzle to atomize the molten metal. The atomizing head, which is composed of contact tip, air nozzle, insulating block and arc shield, etc., is the key part of the spray gun. The earliest atomizing head structure is only composed of a contact tip and an air injection pipe, which is called an open nozzle (as shown in Figure 2-37a). Although this structure is simple, the atomization effect of molten metal is not good, and the particles coming out of the mouth are relatively coarse. The currently used atomizing head structure is to install an air cap to properly seal the arc area and divide it into two atomizing airflows. The arc is properly compressed by the auxiliary secondary atomizing airflow, which is called a closed nozzle (such as Figure 2-37 b). This structure increases the pressure in the arc area, correspondingly increases the jet velocity of the air flow and the arc temperature, strengthens the atomization effect on the molten metal, and makes the sprayed particles more fine.

According to the different power sources for driving the wire, the arc spray gun is divided into electric type, that is, driven by an electric motor; air motor type, that is, driven by an air motor, and pneumatic worm gear type, that is, driven by a pneumatic worm gear. The electric type is suitable for stationary spray guns, and the air motor type is suitable for hand-held spray guns. According to the different ways of pushing the wire, it is divided into push type, pull type and push-pull type. The push type is that the power device outside the spray gun pushes the wire to the spray gun; the pull type is that the power on the spray gun drives the metal wire, and the push-pull type is composed of two pushing methods. The push structure can reduce the weight of the spray gun, but the push wire distance is limited.

Hot information